Line Stop Actuators: What They Are and How They Work

Pipeline maintenance often demands precision, safety, and minimal disruption. In industries where fluids or gases need to move continuously, even a short pause can create significant losses. This is where line stopping methods become essential. At the center of this process is the use of Line Stop Actuators. These devices allow operators to safely control or isolate flow inside a pipeline without shutting down the entire system.

Line stop equipment has transformed the way industries handle repairs, upgrades, and emergency interventions. It makes it possible to seal or redirect flow, all while keeping the system active. Unlike traditional shutdowns, line stopping solutions prevent costly downtime. Operators can work on a section of the pipeline while the rest of the system functions normally.

This blog takes a closer look at line stop actuators. We’ll explore how they function, their advantages, their limitations, and where they are most commonly used. You’ll also understand how they differ from other line stopping equipment and what factors to consider when purchasing or renting. By the end, you’ll have a clear idea of why line stop actuators are such a vital part of modern flow control and how the right provider can help you achieve safe, efficient results.

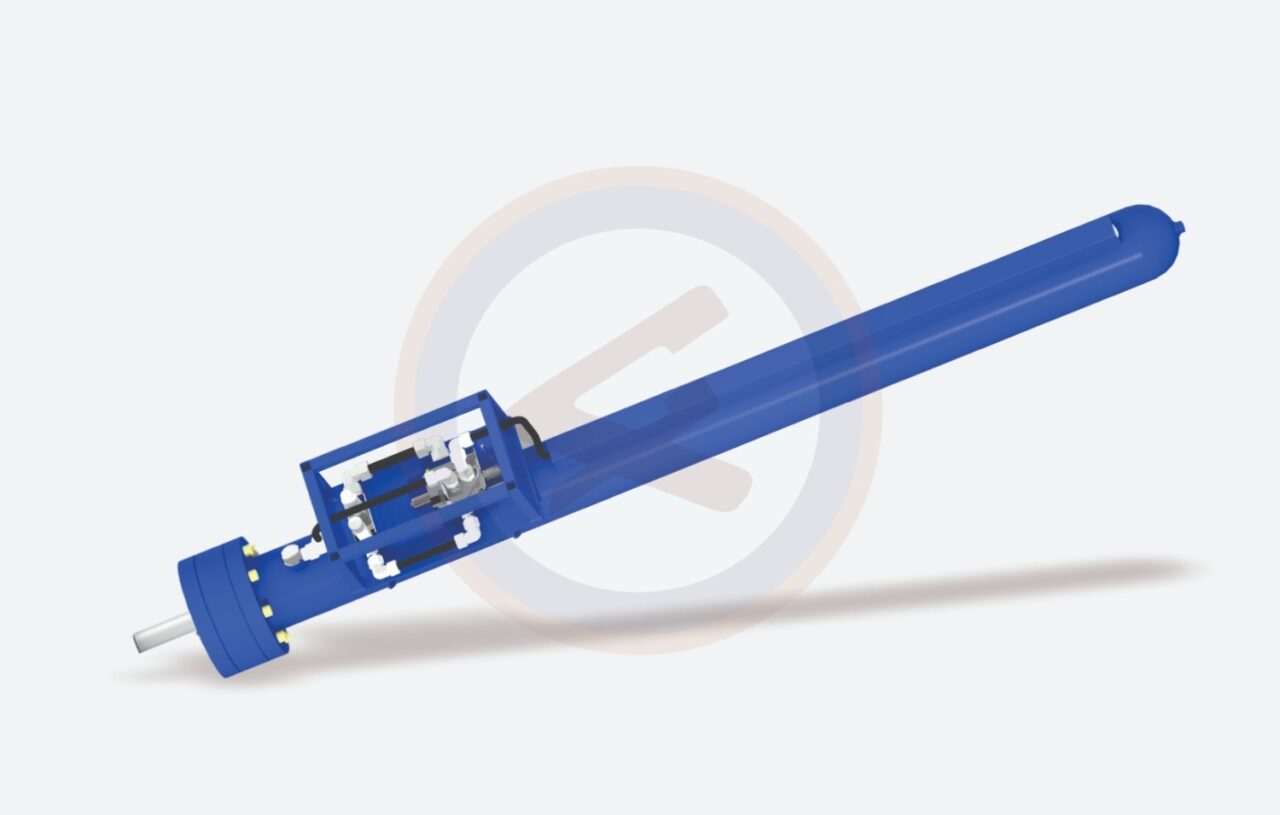

What Is a Line Stop Actuator?

A Line Stop Actuator is a critical part of line stopping equipment. Its primary function is to control the flow inside a pipeline during maintenance or modifications. When used with a line stop machine, it allows operators to block, divert, or isolate flow with precision. The actuator itself is the device that activates the stopping head inside the pipe. This mechanism ensures the flow is sealed or redirected as needed. Without it, line stopping would not be possible. The actuator essentially turns the system from a passive setup into a working solution.

In the broader process of line stopping, terms often overlap. For instance, the “line stop machine” is the overall device, while the actuator is the controlling mechanism within it. Together, these tools form part of what is known as line stop equipment. Depending on the size and pressure of the pipeline, operators can select the right type of actuator for safe performance. Whether in water supply systems, gas pipelines, or chemical plants, actuators give operators control. They turn complex operations into manageable tasks, ensuring pipelines can be serviced without complete shutdowns.

How Line Stop Actuators Work (Step-by-Step)

The working process of line stop actuators follows a structured method:

Step 1: Positioning

Technicians begin by installing the line stop equipment onto the pipeline. This involves securely attaching fittings that allow the actuator to connect.

Step 2: Activation

Once in place, the line stop actuator is engaged. Its job is to control the motion of the stopping head. Depending on design, this might involve hydraulic, pneumatic, or mechanical force.

Step 3: Sealing

The actuator lowers the stopping head into the pipe. This seals the flow, either stopping it entirely or isolating a section.

Step 4: Transition

After sealing, the system can be redirected. Flow may continue at controlled pressure through bypass lines or remain halted while repairs are made.

There are different actuator types. Hydraulic actuators are preferred for high-pressure pipelines because of their strength. Pneumatic actuators suit systems that already rely on compressed air. Mechanical versions are simpler and often used in smaller setups. Each type has its own precision and operating limits, making it important to choose carefully.

Through these steps, actuators transform complex flow control into a controlled, safe process.

Benefits of Using Line Stop Actuators

The use of line stop equipment brings several advantages to operators across industries.

- Uninterrupted Flow: Pipelines remain active even during maintenance. Water, gas, or chemicals continue to flow with minimal interruption.

- Reduced Downtime: Operators avoid costly shutdowns. Work can be completed faster without pausing an entire system.

- Improved Safety: With precise sealing, actuators ensure safety in high-pressure environments. Workers face lower risks.

- Cost Efficiency: Renting or owning line stop machines proves cheaper in the long run compared to repeated shutdowns.

- Flexibility: Actuators adapt to different pressures, materials, and pipeline sizes.

These advantages make line stopping equipment an industry standard. Instead of dealing with production losses, companies rely on actuators for safe, smooth maintenance.

Also read more on 10 Essential Types of Pipeline Fittings and Their Applications

Limitations and Risks

While line stop actuators provide critical support, they also carry some risks.

- Misalignment: If the actuator or line stop machine is not positioned correctly, leaks may occur.

- Failure Risks: Actuator malfunction during operation could result in partial sealing, creating hazards.

- Material Challenges: Some pipeline materials or conditions make line stopping more difficult.

- Skilled Operation: Trained operators are essential. Without expertise, even advanced equipment may fail.

These challenges highlight why line stopping equipment should only be handled by professionals. Following safety guidelines, routine inspection, and proper training significantly reduce risks.

Typical Applications

Line stop actuators have wide applications across industries.

- Municipal Systems: Used in water supply and sewage pipelines for maintenance.

- Industrial Pipelines: Power plants, refineries, and chemical facilities depend on line stopping equipment during upgrades.

- Oil & Gas: Pipeline isolation during maintenance or expansion often requires line stop machines.

- System Modifications: Temporary isolation during pressure testing or valve replacements.

In each case, the ability to stop or redirect flow without a full shutdown saves time, ensures safety, and minimizes service interruptions.

Line Stop Actuators vs. Other Line Stopping Equipment

While all line stopping equipment serves a similar purpose, actuators stand out. The line stop machine represents the larger system, while the actuator provides direct control. Unlike simpler devices, actuators deliver precision. They adjust flow accurately and ensure consistent sealing. For smaller or low-pressure systems, other devices may work. But when safety and reliability are top priorities, actuators are the better choice. They offer more control and are suitable for varied pipeline environments. Choosing between a line stop machine and an actuator often depends on pipeline size, pressure, and operational needs.

Purchasing or Renting Line Stop Equipment

Operators often face a choice between purchasing and renting.

- Purchasing: Best for companies with frequent pipeline work. Owning line stop actuators provides long-term savings.

- Renting: Suitable for occasional needs. Renting line stopping equipment allows access to advanced tools without high upfront costs.

When deciding, operators must check specifications such as pipe diameter, operating pressure, and compatibility. Vendors offering line stop equipment for sale or lease usually provide support for setup and training.

Choosing the Right Line Stop Equipment Provider

Selecting a reliable provider is as important as choosing the right tool. Factors include:

- Proven Track Record: Providers with experience reduce operational risks.

- Safety Certifications: Ensure the equipment meets industry safety standards.

- Compatibility Range: A wide selection of line stop actuators supports different pipeline sizes and pressures.

- Customer Support: Ongoing technical guidance makes a huge difference.

Customer testimonials and real-world applications often reveal how dependable a provider truly is.

Conclusion

Line stop actuators have become essential tools in modern pipeline operations. They allow flow control without shutting down systems, saving time and money while ensuring safety. By understanding how actuators work, their benefits, and their risks, operators can make better decisions. Whether you are exploring line stop equipment for sale or considering rental options, the key is to choose trusted providers. With the right partner, you gain not only reliable line stopping equipment but also the expertise to operate it safely. If your operations demand efficient, safe, and cost-effective flow control, investing in the right line stop machine and actuator system is the next step.