Line / Flow Stop Equipment

Line / Flow Stop Equipment Overview

The line stop equipment is built to isolate the pressurized pipelines and prevent any disconnection in the course of the modifications, repairs, and installation of the valves. The system is made up of line stop machines, plugging heads, housings, and completion fittings- all of which are selected in regard to precision and reliability. F4 produces this equipment as it aligns with ASME standards and has pressure ratings up to ANSI 600# with PN Series. We offer a product range of both small-diameter and over 48-inch pipeline sizes, depending on the requirements of the project. F4 line stop solutions provide reliable performance, reducing downtime, yet keeping operations running.

Manual

Hydraulic

F4 manufactures Sandwich Valves / Slim Valves, with a compact design, provided with a reduced height while meeting all design requirements for the designated pressure classes. We supply manually operated and hydraulically operated sandwich valves.

- Sandwich Valves / Slim Valves

- Line Stop Housing | Line Stop Heads | Sealing Elements

- Line Stop Actuators & Manual Jack Screw

- Power Stop | Pipe Freezing Jackets

Manual

Hydraulic

F4 Manufactures Sandwich Valves / Slim Valves with a compact design that reduces height while maintaining all necessary design parameters for specified pressure classes. We offer both manually and hydraulically operated sandwich valves.

| Type | Size | Pressure Rating |

|---|---|---|

| Manually Operated | 2 Inch to 24 Inch | ANSI 150#, 300#, 600# & PN Series (Higher Pressure Rating can be supplied against specific request or orders) |

| Hydraulically Operated | 18 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) |

Aluminium Sandwich Valve

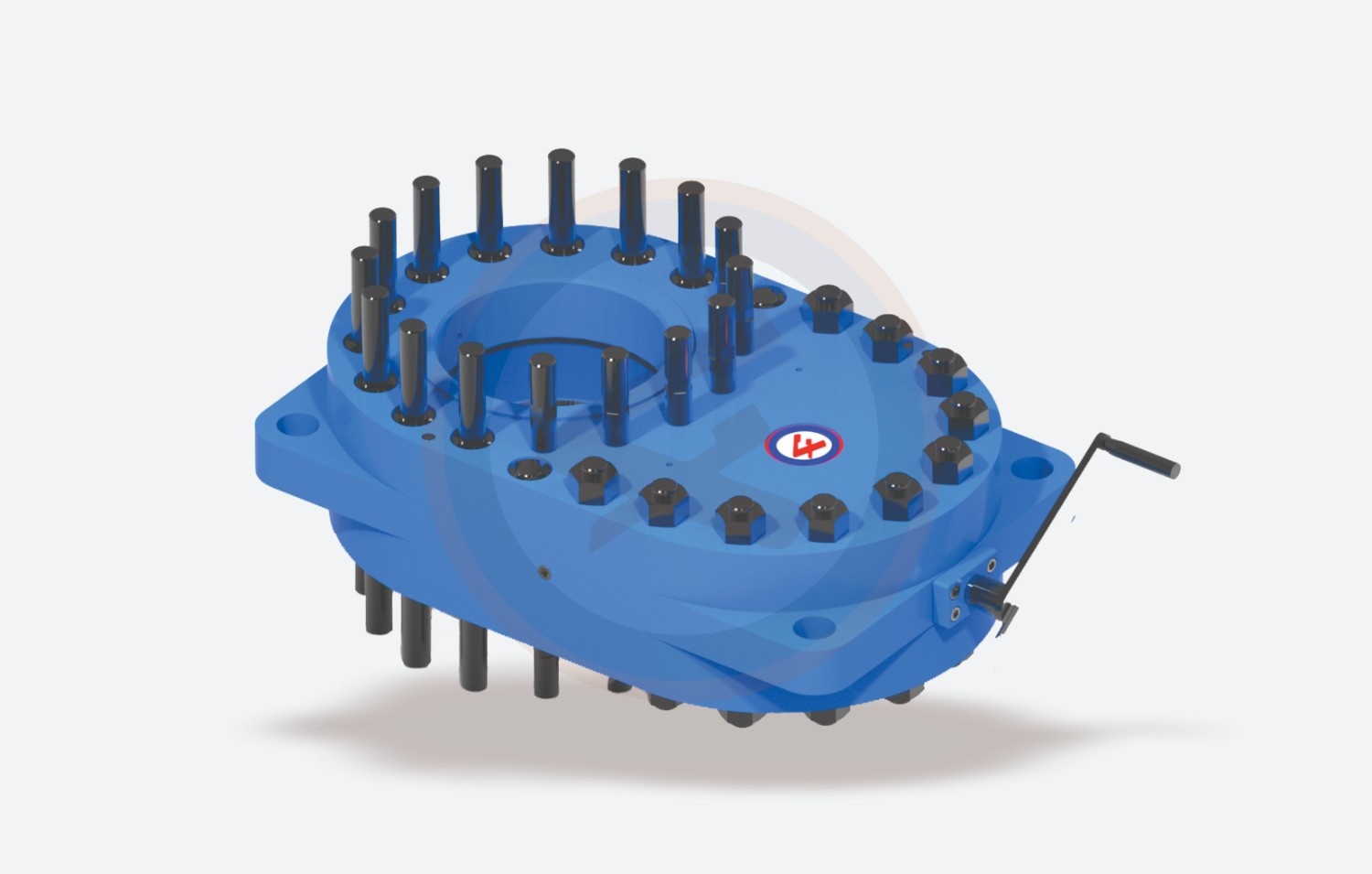

Line Stop Housing | Line Stop Heads | Sealing Elements

| Equipment | Sizes | Pressure Rating |

|---|---|---|

| Line / Flow Stop Housing | 2 Inch to 48 Inch | ANSI 150#, 300# & 600# & PN Series (Higher Pressure Rating can be supplied against specific request/orders) |

| Line Stopping / Plugging Heads | 2 Inch to 48 Inch | ANSI 150#, 300# & 600# & PN Series (Higher Pressure Rating can be supplied against specific request/orders) |

| Sealing Elements | 3 Inch to 48 Inch | NBR, EPDM, Viton, Neoprene, and Polyurethane materials |

(Above 48 Inch can be supplied against specific request/Order)

Mechanical Folding Line Stop Head

F4 designs and manufactures fabricated Mechanical Folding Line Stop Heads for large diameter, low-pressure pipelines, and also supplies line stop equipment for sale. This equipment is best suited for branch connections where equipment attachment is required and where equipment needs to be connected, reducing overall project costs. They can be used on pipelines with operational pressures up to 8 bar and are suitable for line stop operations on pipeline sizes from 14 inches to 102 inches (custom sizes also available on request). The smaller-sized equipment enables the maintenance of the original strength of the pipeline.

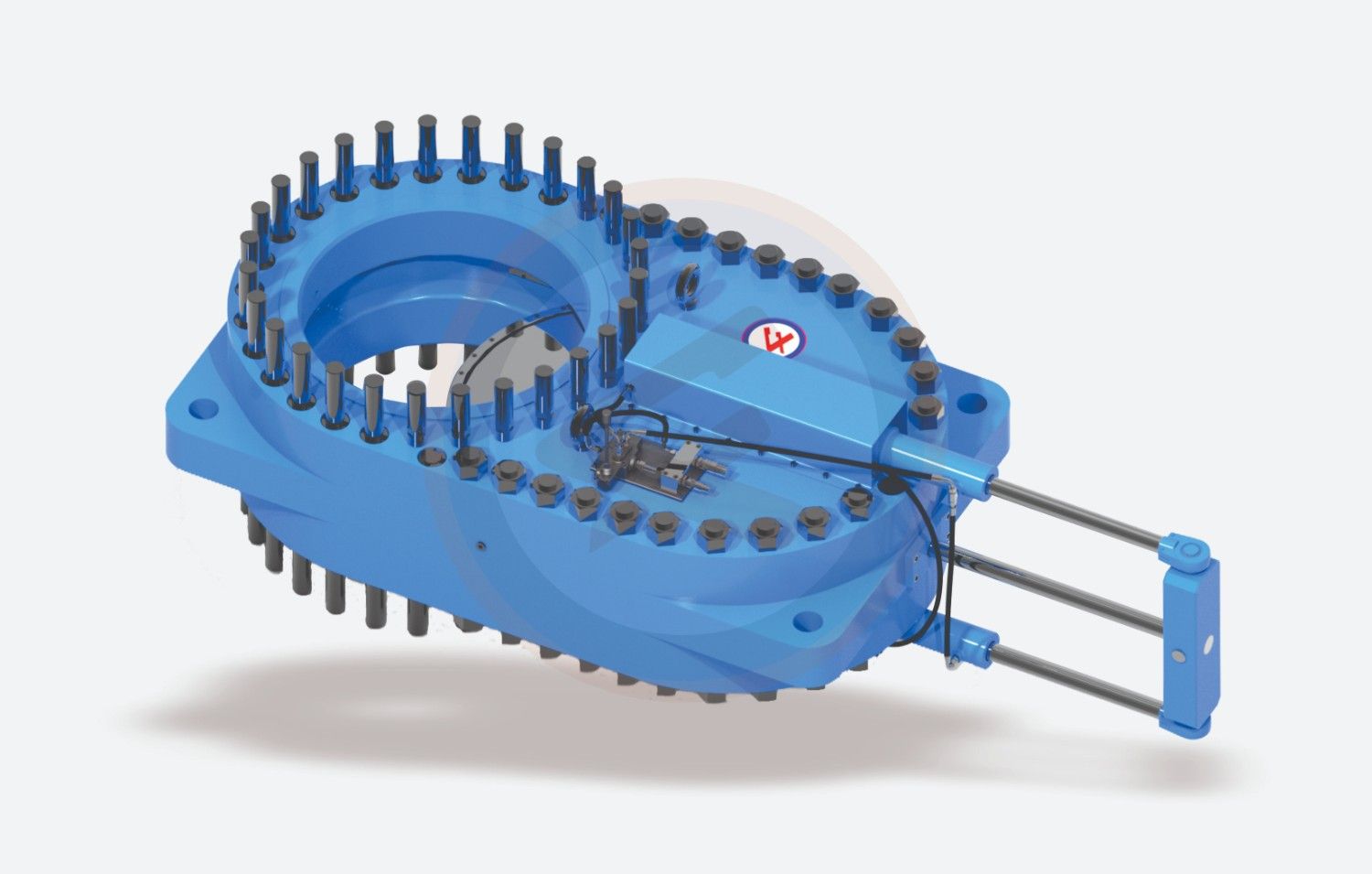

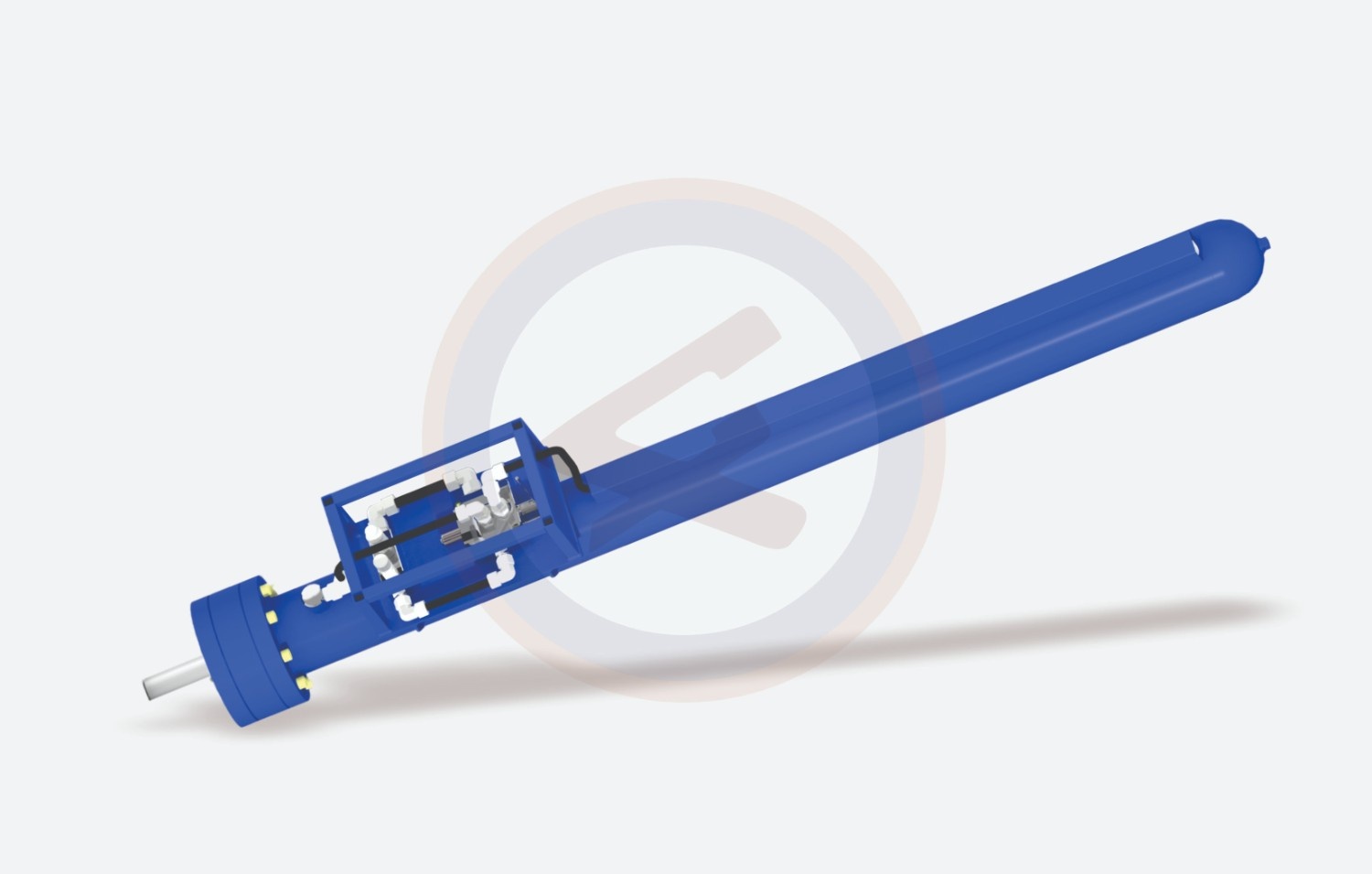

Line Stop Actuators (Hydraulic Actuators)

Line Stop Actuators use hydraulic cylinders to position and actuate the line stop head during the line/flow stop operations.

Hydraulic Actuators

| Part Number | Description | Control Bar Travel | MAOP | Control Bar DIA |

|---|---|---|---|---|

| F4-LSA-0412 | 4 Inch to 12 Inch Hydraulic Actuators | 72 Inch | 1000 | 1480 PSI | 2.5 Inch |

| F4-LSA-1418 | 14 Inch to 18 Inch Hydraulic Actuators | 103 Inches | 1000 | 1480 PSI | 3.5 Inch |

| F4-LSA-1424 | 14 Inch to 24 Inch Hydraulic Actuators | 110 Inches | 1000 | 1480 PSI | 3.5 Inch |

| F4-LSA-2234 | 22 Inch to 34 Inch Hydraulic Actuators | 140 Inches | 1000 | 1480 PSI | 4 Inch |

| F4-LSA-2234 XL | 22 Inch to 34 Inch Hydraulic Actuators | 150 Inch | 1000 | 1480 PSI | 4 Inch |

| F4-LSA-3648 | 36 Inch to 48 Inch Hydraulic Actuators | 150 Inches | 1000 | 1480 PSI | 6 Inch |

| F4-LSA-3648 XL | 36 Inch to 48 Inch Hydraulic Actuators | 180 Inches | 1000 | 1480 PSI | 6 Inch |

| F4-LSA-48 PLUS | And Above 48 Inch | 180 Inches | 1000 | 1480 PSI | 8 Inch |

| F4-LSA-48 PLUS XL | And Above 48 Inch | 200 Inches | 1000 | 1480 PSI | 8 Inch |

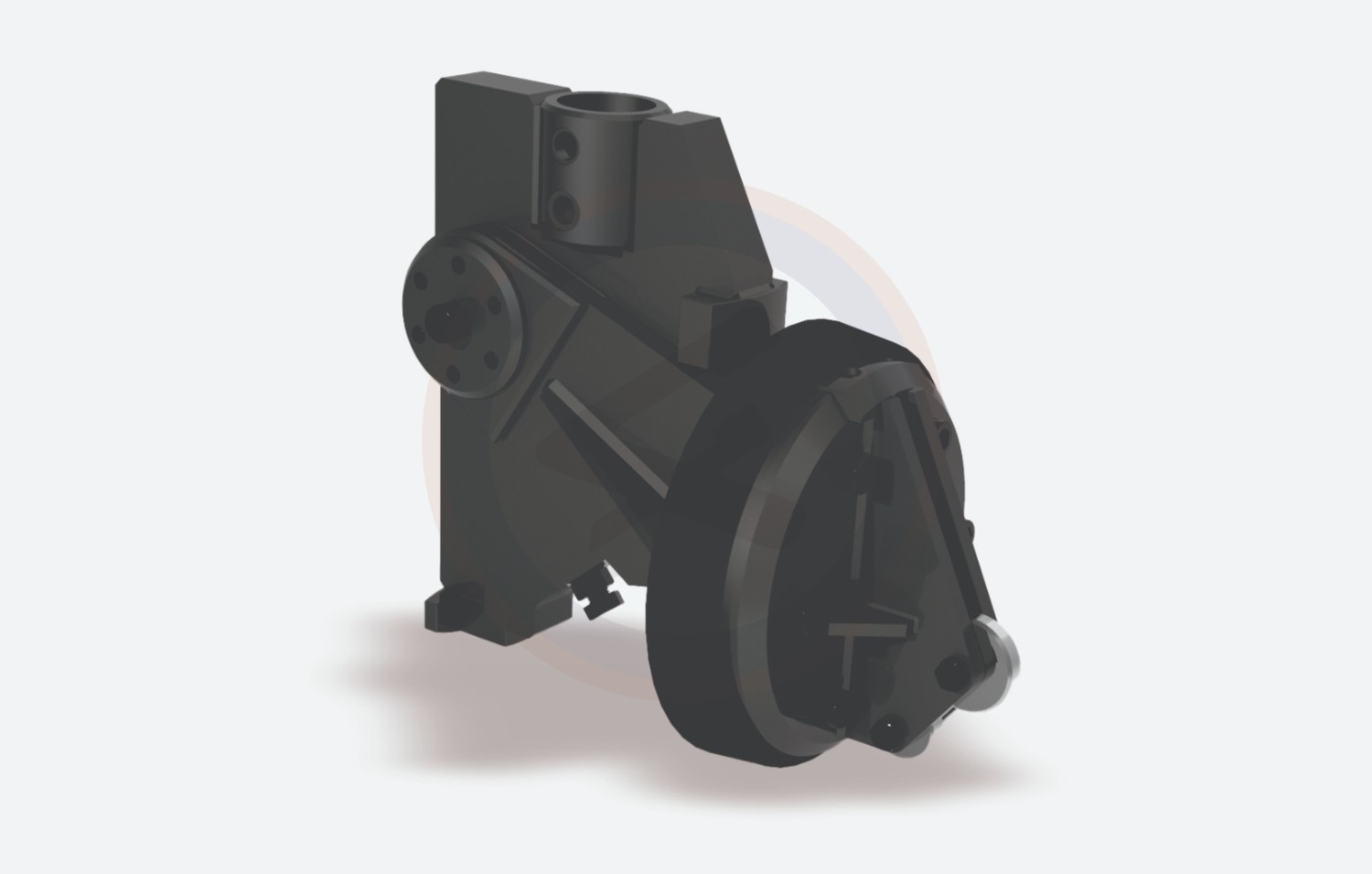

Line Stop Actuators (Manual Jack Screw)

Line/flow stop operations on pipelines below 18 inches are actuated and positioned through the Manual Jack Screw that can be used on high and low-pressure pipelines.

Jack Screw (Manual) Actuators

| Part Number | Description | Control Bar Travel | MAOP |

|---|---|---|---|

| F4-MJS-0203 | 2 Inch & 3 Inch | 30 Inch | 1000 | 1480 PSI |

| F4-MJS-0405 | 4 Inch to 5 Inch | 48 Inches | 1000 | 1480 PSI |

| F4-MJS-0612 | 6 Inch & 12 Inch | 60 Inch | 1000 | 1480 PSI |

| F4-MJS-1424 | 14 Inch to 24 Inch | 72 Inches | 1000 | 1480 PSI |

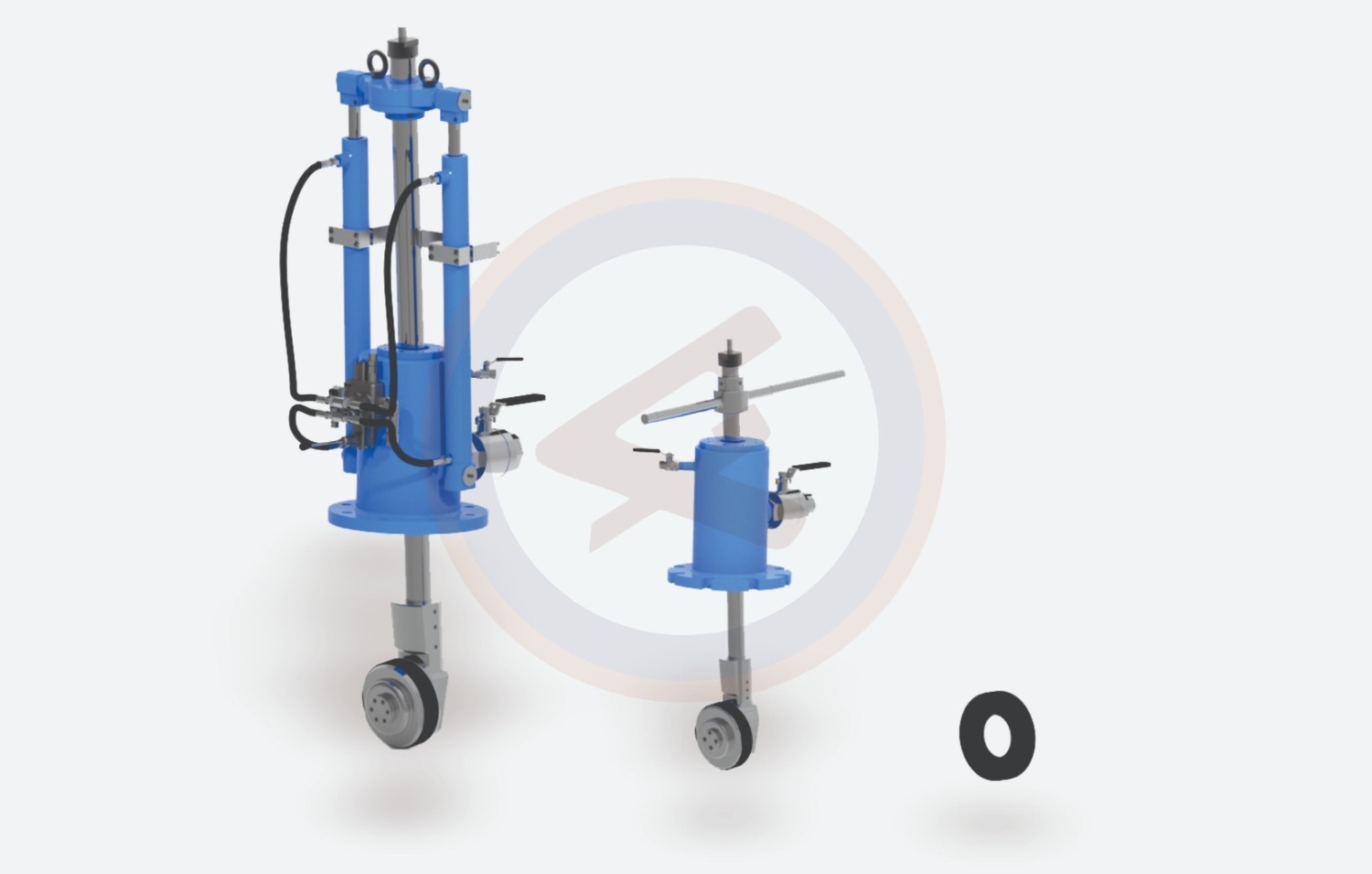

Power Stop

The Power Stop is a piece of equipment that weighs less, ranging in size from 3 inches to 12 inches. It is factory tested to 24 bar and operates at up to 16 bar. The sealing head increases by 20 mm, providing an effective seal in the pipe, irrespective of ovality. The power stop that is operated hydraulically is supplied with a power unit. F4 has also developed a cleaning tool that gives the contractors an opportunity to look inside the pipeline and clear any deposits before installing the power stop heads. The system also has a tool for removing lost coupons.

| Operation Type | Sizes |

|---|---|

| Manually Operated | 3 Inch, 4 Inch, 5 Inch, 6 Inch & 7 Inch |

| Hydraulically Operated | 6 Inch, 7 Inch, 8 Inch, 9 Inch, 10 Inch & 12 Inch |

Pipe Freezing Jackets

The Pipe Freezing Jackets freeze the product inside the pipe, creating a solid ice plug that will enable modifications or valve exchanges without the need to shut down the system or drain the product out of the pipeline.

Size : ½ Inch to 24 Inch NB Pipes (Above 24 Inch can be supplied against specific request/orders)

MOC : Aluminium / SS 304

Why Choose Line/Flow Stop Equipment?

- Allows maintenance, repair, or modification without shutting down the system entirely

- Perfect to be used in piping line stop diversions, re-routing, or adding new portions

- Facilitates safe shutdown and gradual system isolation

Key Features and Applications of Our Line/Flow Stop Equipment

- It allows safe operations with controlled temporary isolation of active pipelines.

- Enables valves to be installed, branches to be connected, or sections to be replaced without draining

- Operates well under a low-pressure and high-pressure pipeline system

- Compatible with carbon steel, ductile iron, PVC, GRE, and other frequently used piping materials

- The ability to work under severe temperature and pressure conditions is designed with safety in mind

- Designed to suit particular pipeline diameters, lengths, and types of pressures

Why Choose F4

- Engineering Excellence Proven

Exacting hardware developed to give reliable performance in harsh field environments. - Full Project Support

We offer a fully integrated customer support and on-site technical guidance during initial design and commissioning. - Custom-Built Solutions

Customization of designs to meet specific operational needs that are very safe and efficient in operation.

Frequently Asked Questions

- 1. How quickly can the equipment be installed and removed on-site?

It actually depends on the size and type of the pipeline, but the F4 system is engineered to minimize downtime and keep operations running smoothly for any pipeline stop project.

- 2. Which pipe material is compatible with line stopping equipment?

F4 line stop machines and line stop valve are compatible with carbon steel, ductile iron, PVC, GRE, and other commonly used pipeline materials.

- 3. Do we need any specialized training to operate this system carefully?

Yes. We provide operator training and technical support to ensure efficient and safe operation. Minimal training is needed for smaller systems, while double line stop units may require trained personnel.

- 4. Is a temporary or rental deployment option available?

Yes, F4 offers line stop equipment for sale for short-term or project-based needs, allowing flexible deployment without buying the whole equipment