Hot Tap / Line Stop Fittings

Hot tap / line stop fittings are specialized fittings that are used for safely connecting new pipelines to existing, or modification of pressurized pipelines without altering the parameters of the main line

Imagine a pipeline is like a big water hose that never stops running. If you had to fix something in the middle of it, normally you’d need to shut it off—but that would waste time and money. Hot tap / line stop fittings let you safely cut into or block off a section of that pipeline while it’s still in use, so there is no interruption of the flow.

These Fittings can be manufactured from ½” to 48” of ANSI 150# , 300# , 600# and of various materials such as mild steel , carbon steel , stainless steel etc .

- Hot Tap / Line Stop Full Encirclement Split Tees

- Hot Tap / Line Stop Mechanical Tees

- Hot Tapping Nozzle

- Thread-O-Ring Fitting

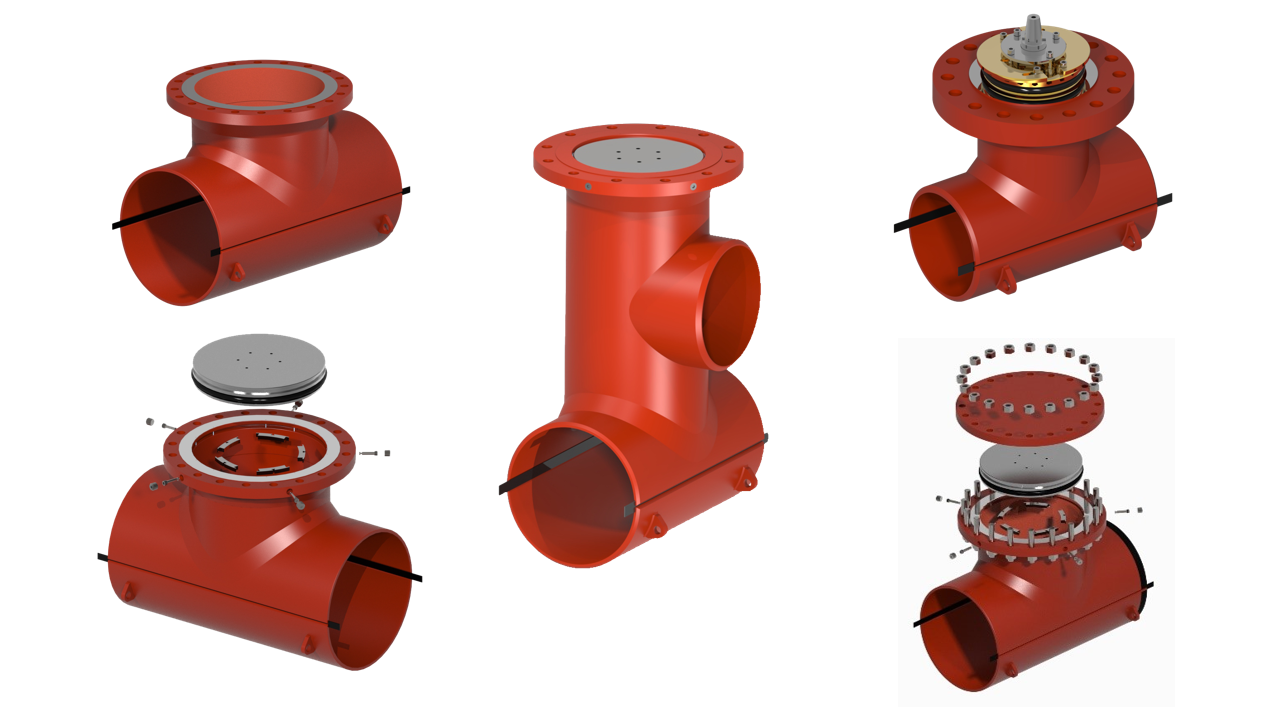

Hot Tap / Line Stop Full Encirclement Split Tees

Hot Tap / Line Stop Full Encirclement Split Tees are essential fittings for hot tapping or line stopping operations. F4 supplies both fabricated and forged/extruded types of full encirclement split tees. These tees can be supplied with a flow-through guide bar for hot tapping operations, or with an L-O-R plug or cam lock plug for line stopping operations, depending on customer requirements.

Hot Tap / Line Stop 3-Way Tees are similar to full encirclement split tees but feature an additional branch connection. This provides multi-branch connections in hot tapping operations or allows for temporary/permanent bypasses in line stopping operations.

| Sizes | Pressure Rating |

|---|---|

| 2 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) | ANSI 150# | 300# | 600# & PN Series |

| (Higher Pressure Rating Available Upon Special Request) | |

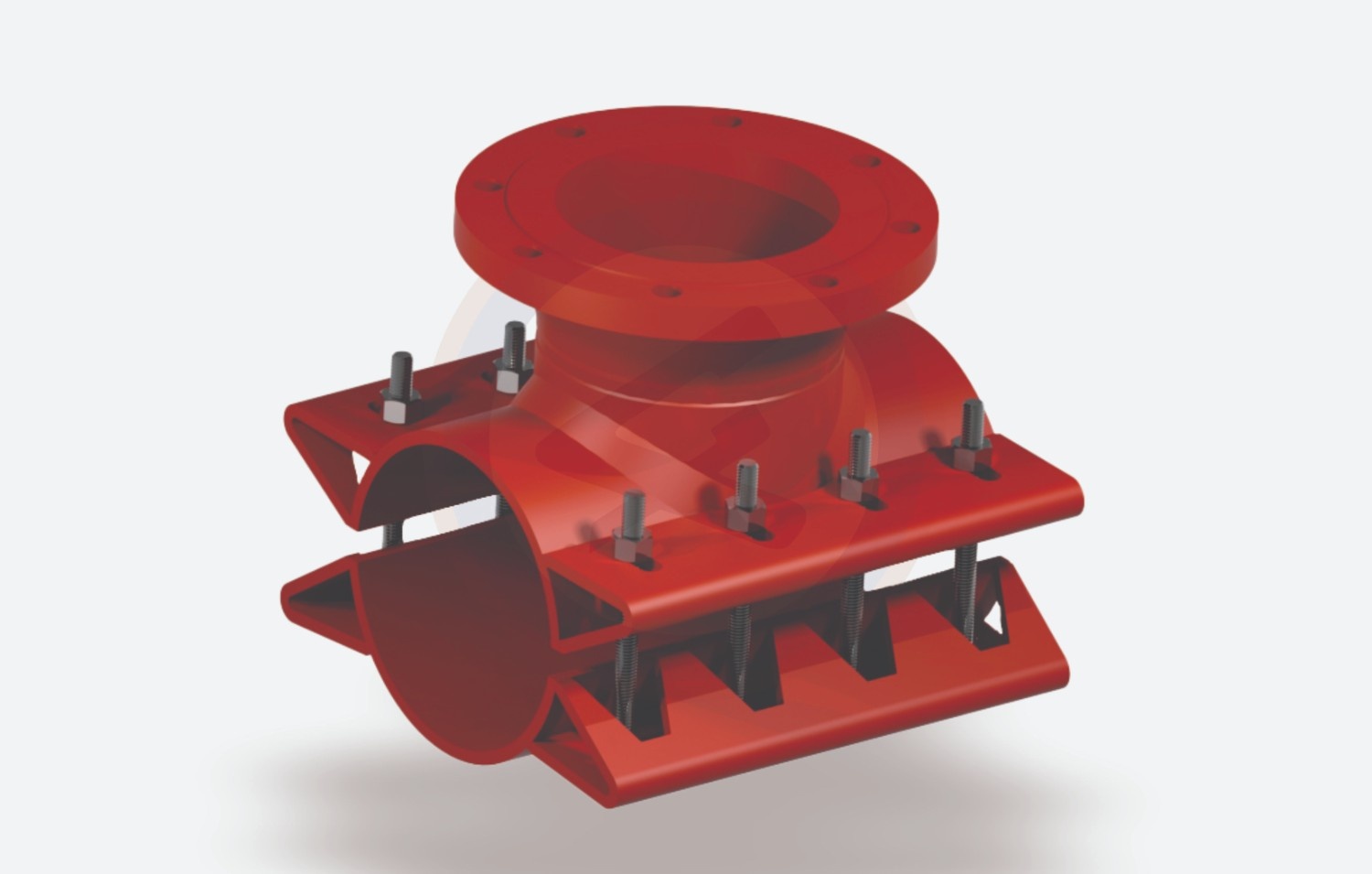

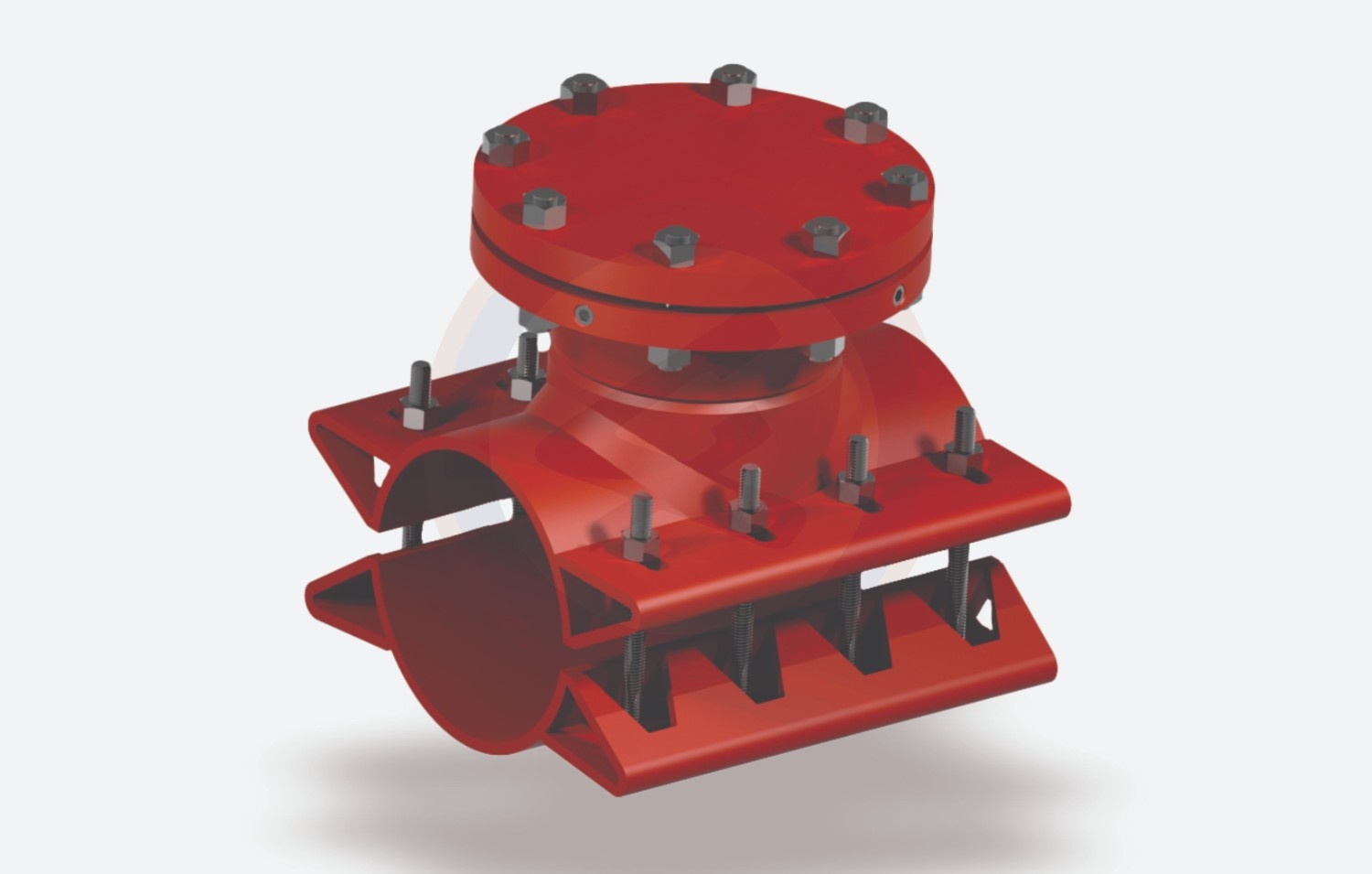

Hot Tap / Line Stop Mechanical Tees

Hot Tap Mechanical Tee

Line Stop Mechanical Tee

These Hot Tap / Line Stop Mechanical Tees are similar in design and construction to full encirclement split tees, but instead of welding, these split tees are fastened to the mainline using fasteners on both longitudinal sides. These are generally recommended for low-pressure operations.

| Sizes | Pressure Rating |

|---|---|

| 2 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) | ANSI 150# & PN SERIES |

Hot Tapping Nozzle

Flanged Nozzle with RF Pad

Flanged Nozzle with RF Pad are used in hot tapping operations where the tapping size is smaller than the mainline size. These fittings are of fabricated type.

Flanged Nozzle

Flanged Nozzle are typically used in situations where the design pressure of the pipeline is relatively low. These fittings are of fabricated type.

Weld-O-Let Flange

Weld-O-Let Flange are employed for hot tapping when the tapping size is significantly smaller than the mainline size. These fittings are of fabricated type.

| Fittings | Sizes | Pressure Rating |

|---|---|---|

| Flanged Nozzle with RF Pad | 2 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) | ANSI 150# & PN SERIES |

| Flanged Nozzle | 2 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) | ANSI 150# & PN SERIES |

| Weld-O-Let Flange | 2 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) | ANSI 150# & PN SERIES |

Thread-O-Ring Fitting

Thread-O-Ring Fitting are specialized components essential for line stopple operations. They facilitate pressure balancing between the mainline and the line stop operation system. These fittings also enable the draining and venting of the product from the isolated section.

| Sizes | Pressure Rating |

|---|---|

| 2 Inch & 3 Inch | ANSI 150#, 300#, 600# & PN Series |

Types

1. Hot Tap and Line Stop Fittings

F4 specializes in manufacturing of different sizes & Pressure ratings hot tap and line stop fittings that facilitate live work on pipelines without a shutdown. We standardly manufacture from ½” to 48” of ANSI 150# | 300# | 600#

2. Innovative Pipeline Fittings

We are one of the leading manufacturers for innovative pipeline fittings such as Dismantling Joints, Mechanical Couplings, Mechanical Flange Adaptors, Stepped Mechanical Coupling etc. these fittings are used in low pressure utility lines.

3. Specialized Pipeline Products

F4 specialized pipeline fittings products include encapsulation/repair clams and Uni-Valve® systems designed for low pressure utility and process lines.

Applications

Pipeline fittings have multiple applications across a number of industries, including:

- Oil and Gas

- Chemical & Fertilizers

- Steel & Aluminum plants

- Utility Sectors

- Industrial Process Lines

- Construction

Processes

The installation of the hot tap / line stop pipeline fittings depends on the type of fitting it could be welded or mechanical bolting type split tee. Once installed on to the live pipeline then the hot tapping or line stopping operation could be carried out.

Benefits

- Enhances the pipeline integrity for hot tapping or Line Stop Operation

- Reduction in downtime and operational costs without interruptions to regular operations.

- Versatility across different pipe materials, sizes and pressure ratings.

- Compliance with international industry standards delivering reliable and safe performances.

Why F4?

- It is the only company in India capable of manufacturing specialized pipeline fittings and equipments of various sizes and design pressures on different product lines

- F4 has its in-house facility with state of the art manufacturing along with its own design team and testing of pipeline products, fittings and accessories .

- All pipeline fitting manufactured by F4 are designed as per ASME Code

- For high / low pressure product lines.

- We provide customized solutions tailored to suit the clients’ specific technical requirements and site conditions.

Frequently Asked Questions

- What are hot tapping and line stopping operations, and how do F4’s products facilitate these processes?

- What size range and pressure ratings are available for F4’s pipeline fittings?

- How do F4’s universal wide-tolerance mechanical couplings benefit pipeline installations?

- What are the specialized solutions available from F4 for pipeline modification or repair?

- What sets F4 apart from other manufacturers of pipeline fittings?

Hot Tapping is a specialized method of creating a branch connection to existing pipelines, vessels or process equipment while the system remains under pressure.

Line or Flow Stopping is a critical technique used to halt the flow within a pipeline while optionally providing a bypass to maintain the downstream supply.

F4 designs & manufactures specialized fittings and equipment for both hot tap and line stop operations in bolting or weld type. These fittings are designed as per ASME codes and come in sizes ½” – 48” with pressure ratings from ANSI 150# to 900#

F4 produces pipeline fittings in 2 Inch to 48 Inch standard sizes (up to 102 inches on special request) with pressure ratings such as ANSI 150#, 300#, 600#, 900#, and equivalent PN series. Our water utility fittings are available from DN50 to DN2400 with ratings from PN16 to PN60 and Class 150 to 900, addressing nearly any pipeline size or pressure need in Oil and Gas, Water, and Industrial Applications.

F4’s mechanical couplings feature a tolerance on pipe diameter, accommodating various materials and dimensional variations with precise measurement. We provide end-load-resistant connections while allowing angular deflection for alignment adjustments. Installation requires only a torque wrench, reducing labor and specialized tools.

F4 has Encapsulation / Repair Clamps for rapid sealing of leaks with no welding required, the pioneering Uni-Valve® technology for introducing control points to existing pipelines without shutting down, and Pipe Freezing Jackets that generate temporary ice stops in pipelines for modification with no draining necessary.

With over 3 decades of experience, dedicated staff, State of the art manufacturing and testing facility every project is tailored to unique requirements and conditions, but with industry quality standards.