Hot Tapping Machine Accessories

Hot tapping machine accessories provide aid in safe, accurate, and efficient tapping of live pipelines. These are special cutters, pilot drills, sealing components, and adapters to suit specific project needs. The F4 accessories are designed and manufactured to be robust, compatible, and easy to install, and therefore, the hot tapping machines can deliver optimally under different site conditions.

- Cutters | Pilot Drills

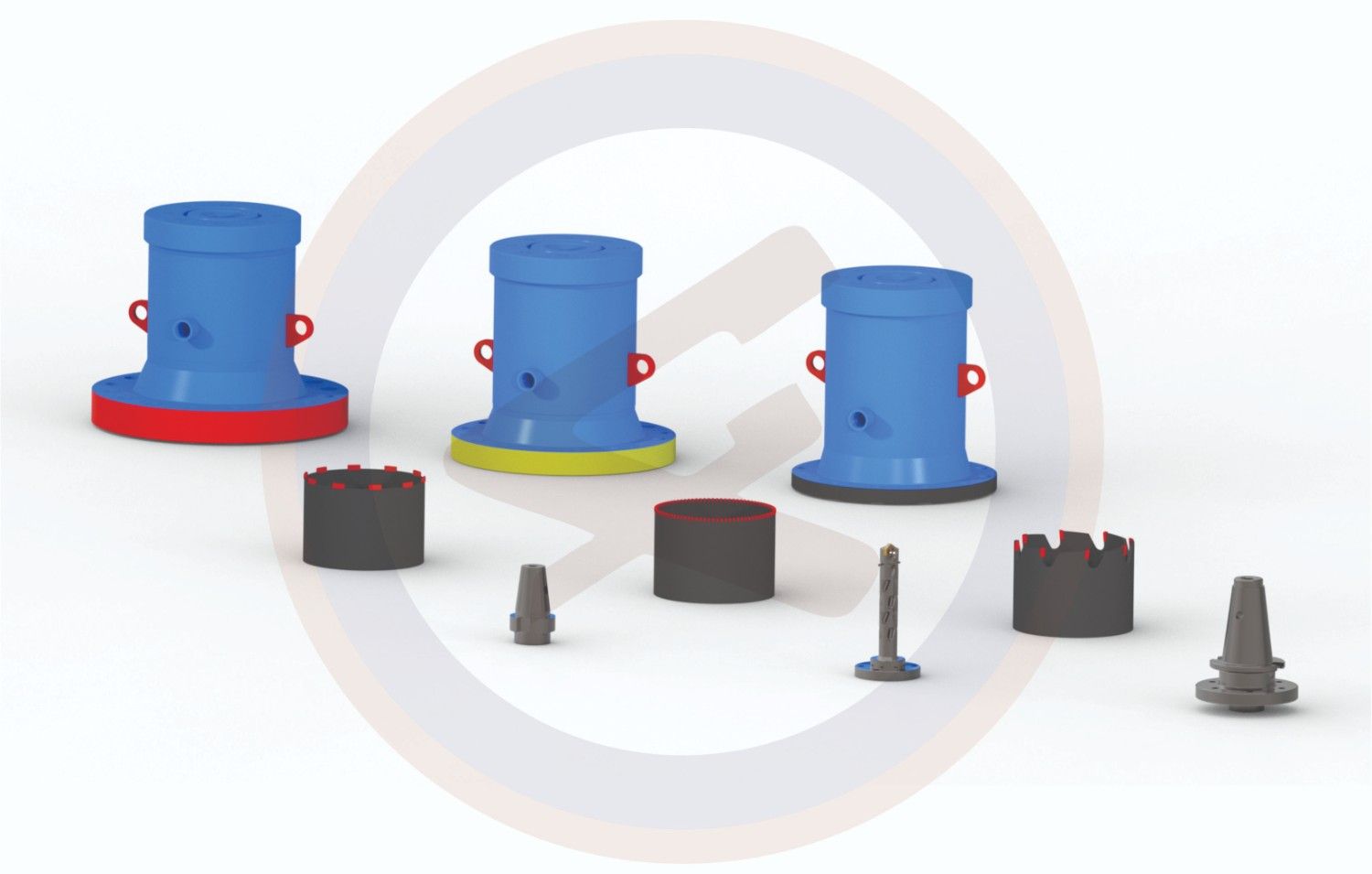

- Hot Tap Cutter Housing / Hot Tapping Machine Adaptors

- Hot Tap Cutter / Plug Holders

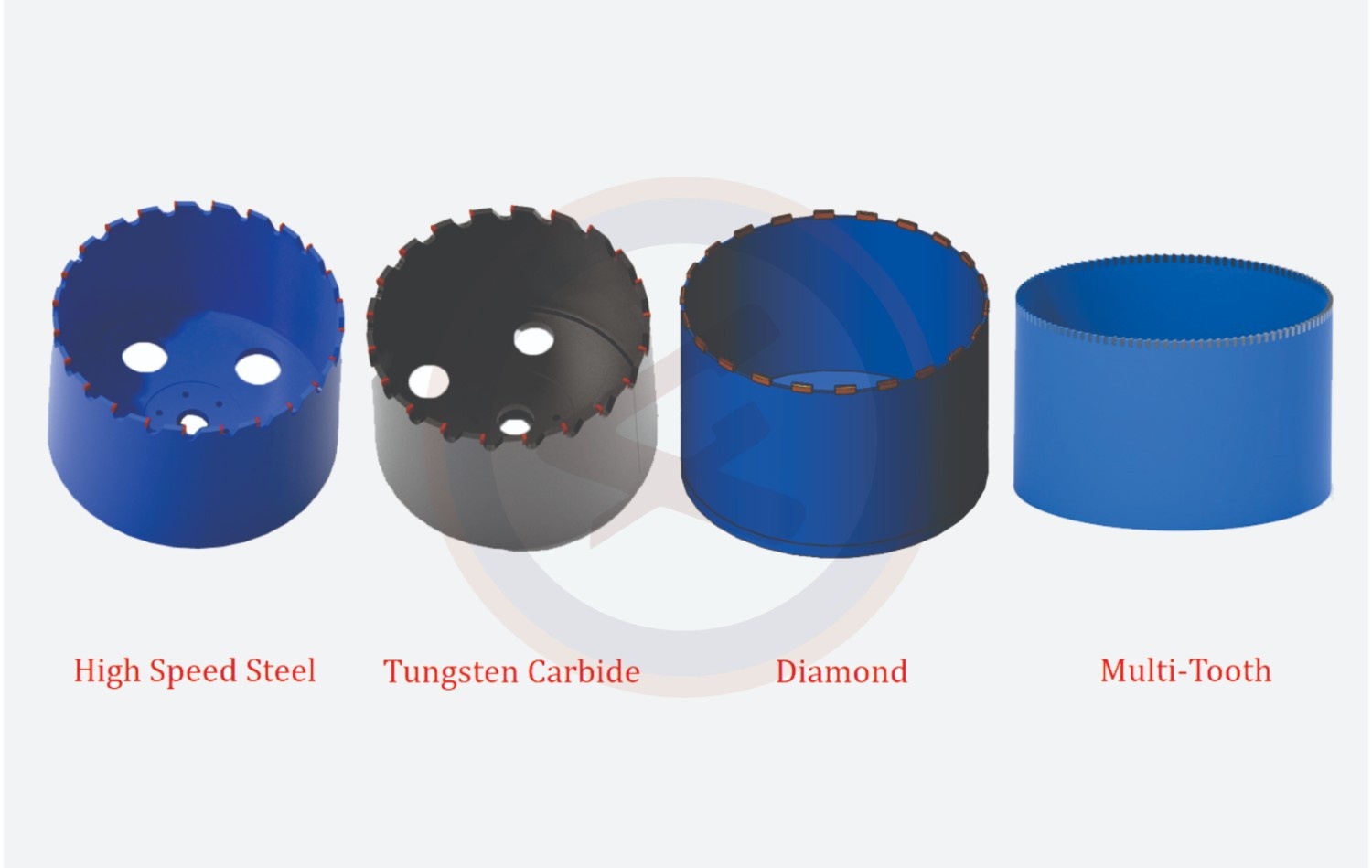

Cutters | Pilot Drills

Hot Tap / Line Stop Cutters

F4 manufactures hot tap cutters and line stop cutters that are precision-engineered in any size between 3 inches to 48 inches. These are cutters compatible with all the major known hot tapping machine types used internationally and can be used to cut a large variety of pipeline materials and cutting demands.

Hot Tap / Line Stop Pilot Drills

These pilot drills come with high-quality, easily replaceable insert-type drilling spades to make the on-site maintenance easy. They are designed to be precise on pipelines made of different materials and thicknesses of the wall, and are reliable in penetration and strength.

Hot Tap / Line Stop Cutter Housings

F4 produces a line of heavy-duty hot tap cutters housings that are available in 3-inch to 48-inch sizes and are ANSI 150#, 300#, and 600# pressure rated. These housings offer the necessary structural integrity to the hot tapping process and guarantee safe, stable, and accurate operation in a variety of working environments.

| Accessory | Cutter | Pilot Drills |

|---|---|---|

| Sizes | 3 Inch to 48 Inch | 2 Inch to 48 Inch |

| Type | HSS | Tungsten carbide | HSS + TC | Diamond | HSS or TC multi tooth | Threaded | Flange Mounting |

(Above 48 Inch can be supplied against specific request/Order)

Cutter Housing

Tri Bar Cutter Housing

F4 Manufactures and supply 2 Inch to 48 Inches Cutter Housing. F4 manufactures and supplies cutter housings ranging from 2 inch to 48 inches with ANSI 150#, 300#, 600# class and PN series pressure ratings. We can also manufacture cutter housings and tapping adaptors above 48 inches and 600 class as per customer requirements. F4’s cutter housings/tapping adaptors, including 4-inch 600# RTJ, 6-inch 600# RTJ, and 8-inch 600# RTJ are compatible with any reputed make hot tapping machines.

| Sizes | Class |

|---|---|

| 2 Inch to 48 Inch | ANSI 150#, 300#, 600# Class & PN Series |

| (Above 48 Inch can be supplied against specific request/Order) | |

Hot Tap Cutter / Plug Holders

F4 Manufactures a range of Hot Tap Cutter / Plug Holders for its various models of hot tapping machines, most of which are compatible with all reputed make hot tapping machines.

| Sizes |

|---|

| 2 Inch to 48 Inch |

| (Above 48 Inch can be supplied against specific request/Order) |

Accessories

Hot tap / Line Stop Cutters: F4 manufactures hot tap / line stop cutters ranging from 3 to 48 inches that are compatible with and adaptable to all internationally recognized or reputable hot tapping machines. They are suitable for various cutting ranges and pipeline materials.

Hot Tap / Line Stop Pilot Drill:These drills are fitted with high-quality ‘insert type’ drilling spades on their tips, which can be easily replaced onsite. The pilot drills are engineered to drill into pipelines of various materials and thicknesses.

Hot Tap / Line Stop Cutter Housings: The cutter housing provides structural foundation for the hot tapping process. We manufacture from 3” to 48” Housings having pressure rating of ANSI 150# , 300# , 600# .

Benefits

1. No Shutdown Required

A primary advantage of using hot tapping machines is the ability to make connections to an operating pipeline without needing a shutdown. This cuts down on downtime and production losses.

2. Cost Efficiency

The entire process removes the requirement for traditional shutdown procedures; hot tapping machines bypass the long and expensive procedure of shutdowns, draining, and refilling.

3. Environmental Protection

On a larger operational scale, hot tapping machines have helped prevent the release of greenhouse gases, especially methane, resulting in a net positive for the environment.

4. Safe and Effective Method

Hot tapping machine manufacturers have fine-tuned the procedural measures to be as safe and secure as possible. The possibility to make new connections while systems remain running reduces risks surrounding shutdowns and restarts.

Hot Tapping Machine Applications

Hot tapping machines are usually used in. The hot tapping method allows for the installation of new connections without disrupting water systems. Additionally, when repairs are necessary water hot tapping machine technology helps in creating bypass systems for larger undertakings. Hot tap machines in UAE operations facilitate attaching monitoring equipment to active water systems.

Specialized seals and materials are required for this challenging setting. The market for hot tap machine accessories in the Middle East continues to grow as infrastructure expansion projects require more frequent integration with existing pipeline systems

The Middle East’s rapid development has created a demand for water hot tapping technology, especially in the UAE. Hot tap machines in the UAE require meeting stringent standards due to the region’s water and oil infrastructure.

F4 manufactures and exports hot tap machines accessories in the Middle East that not only meet the uncompromising regulations but also support the unique needs for the region.

These machines have to be able to withstand the region’s extremely high temperatures and sandy environment. The market for hot tap machine accessories in the UAE continues to grow exponentially as expansion projects require more frequent irrigation resources.

F4 Offers:

Standard Machines

F4 offers multiple standard models with varying boring bar travel lengths:

- Small range machines (F4 6-18, F4 6-24, F4 6-28, F4 6-30, F4 8-40) covering ½ inch to 8 inches tapping ranges.

- Medium to large hydraulic machines with extended boring bar travel lengths for larger diameter applications.

- Extra-large machines (F4 96-120, F4 96-150, F4 96-180) capable of tapping range from 24 inch to 96 inches.

Specialized Machines

F4 manufactures several types of specialized hot tapping machine variants:

1. Pressure Balancing System Machines

These machines feature compensation cylinders that equalize pipeline and sea pressure, reducing stress on internal components. They’re specifically designed for:

- High-pressure tapping operations

- Subsea applications

- Handling pressures up to 2175 psi (150 bar)

2. Tribar Hot Tapping Machines

F4’s lightweight and portable tribar machines are engineered for:

- Low-pressure utility services like chilled water pipelines.

- Air/nitrogen pipelines in pharmaceutical facilities.

- Areas with space constraints, such as malls and hotels.

- Easy transport via elevators in high-rise buildings.

3. Drive System Variants

The company produces machines with multiple drive options:

- Air-driven (Pneumatic) machines, notably being the first Indian company to supply these to Oil and Gas companies.

- Hydraulic-driven machines with similar designs but different power requirements.

- Manual operation options for smaller models.

Why Choose Hot Tapping Machine Accessories?

- Allow pressurized connections to be made safely without system shutdown

- Perfect to use as tie-ins, inserting measurement devices, or carrying out controlled pipeline adjustments

- Minimize the costs of downtimes by removing the necessity of full system isolation

Key Features and Applications of Our Hot Tapping Machine Accessories

- Fits most hot tapping machines on various pipeline sizes and pressures

- Intended to cut precisely and enter live pipelines cleanly

- They are made using high-grade materials like carbon steel, stainless steel, and alloy steel to make them durable

- Applicable in oil & gas, petrochemical, water supply, and industrial pipeline networks

- Proven to work safely under different temperature and pressure levels

- They can be obtained in standard and customized forms to suit a particular operational requirement

Why Choose F4

Uninterrupted Operations

Allow pressurized connections to be made safely without shutting down the system

Why Choose F4

Versatile Pipeline Integration

Perfect to be used in tie-ins, the introduction of measurement instruments, or controlled pipeline alterations

Why Choose F4

Cost & Time Efficiency

Minimize the cost of downtime by avoiding the isolation of the entire system

Frequently Asked Questions

- Which hot tap cutters should I use for my pipeline?

- Can I tap a live pipeline without shutting it down?

- How easy is it to install or replace these accessories on-site?

- What safety measures should be followed when using these accessories?

- How durable are hot tapping machine accessories, and how do I maintain them?

At F4, we help you choose the right hot tap cutters that align with your pipeline’s material, diameter, and wall thickness. We design it in such a way to ensure safe, precise, and efficient tapping operations for a wide variety of pipelines.

Yes. Our hot tapping machine accessories are specifically designed for live tapping, allowing you to make connections or even to perform tie-ins safely without stopping the flow.

We design our hot tapping machine accessories in such a way that it is easy to install and replace, minimizing downtime and ensuring smooth on-site operations.

For safe operation, always pressure-test the pipeline before any use, add proper sealing components, and ensure a trained person is using it. At F4, we provide guidance and training for the safe use of these hot tapping machine accessories.

Our hot tap cutters and accessories are built for long-term usage and for multiple projects. Ensuring Routine inspection, cleaning, and timely replacement of any dead components, maintaining its optimal performance. F4 also provides technical support to help you maintain your accessories more efficiently.