Hot Tap / Line Stop Fittings

Hot tap/line stop fittings are specialized fittings that are used for safely connecting new pipelines to existing, or modifying pressurized pipelines without altering the parameters of the main line

Imagine a pipeline is like a big water hose that never stops running. If you had to fix something in the middle of it, normally you’d need to shut it off, but that would waste time and money. Hot tap fittings and line stop fittings let you safely cut into or block off a section of that pipeline while it’s still in use, so there is no interruption of the flow.

These Fittings can be manufactured from ½” to 48” of ANSI 150#, 300#,600#, and of various materials such as mild steel, carbon steel, stainless steel, etc.

- Hot Tap / Line Stop Full Encirclement Split Tees

- Hot Tap / Line Stop Mechanical Tees

- Hot Tapping Nozzle

- Thread-O-Ring Fitting

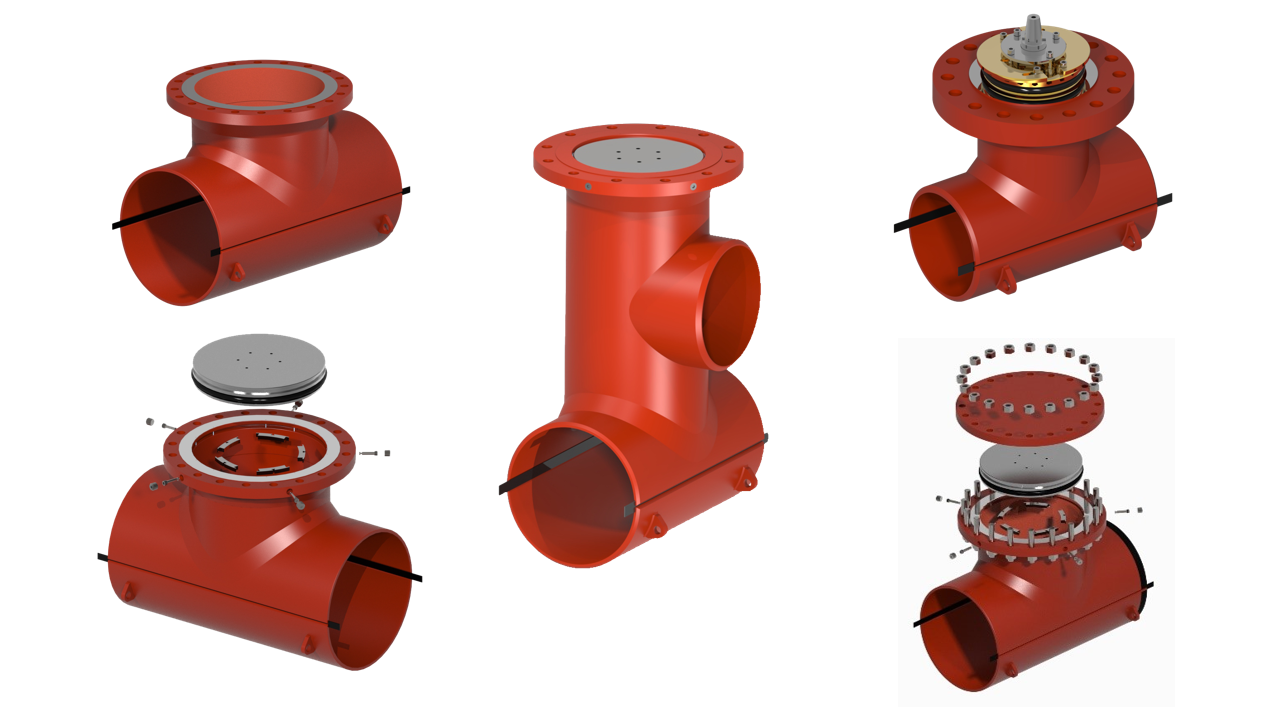

Hot Tap / Line Stop Full Encirclement Split Tees

Hot Tap / Line Stop Full Encirclement Split Tees are essential fittings for hot tapping or line stopping operations. F4 supplies both fabricated and forged/extruded types of full encirclement split tees. These tees can be supplied with a flow-through guide bar for hot tapping operations, or with an L-O-R plug or cam lock plug for line stopping operations, depending on customer requirements.

Hot Tap / Line Stop 3-Way Tees are similar to full encirclement split tees but feature an additional branch connection. This provides multi-branch connections in hot tapping operations or allows for temporary/permanent bypasses in line stopping operations.

| Sizes | Pressure Rating |

|---|---|

| 2 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) | ANSI 150# | 300# | 600# & PN Series |

| (Higher Pressure Rating Available Upon Special Request) | |

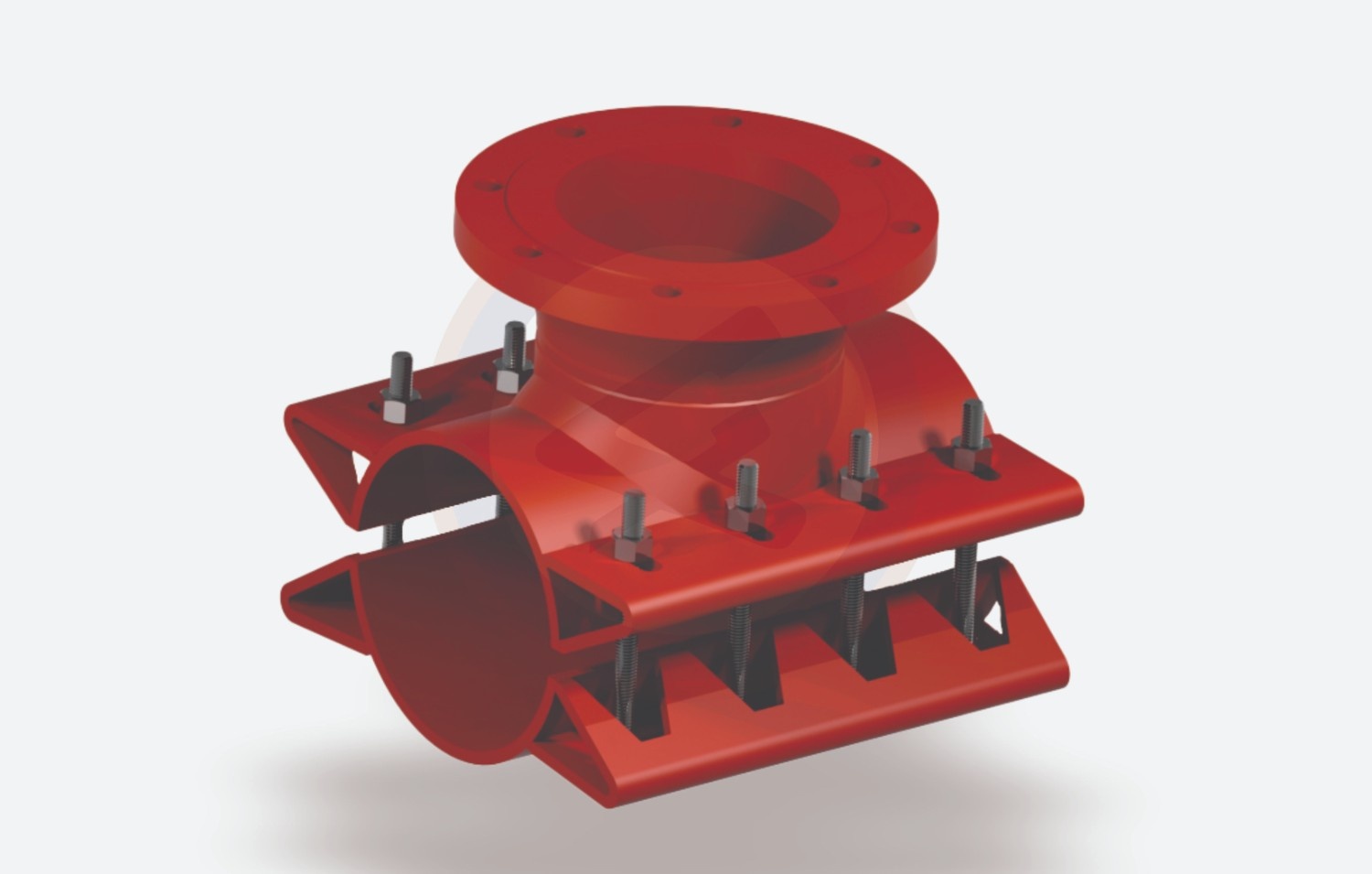

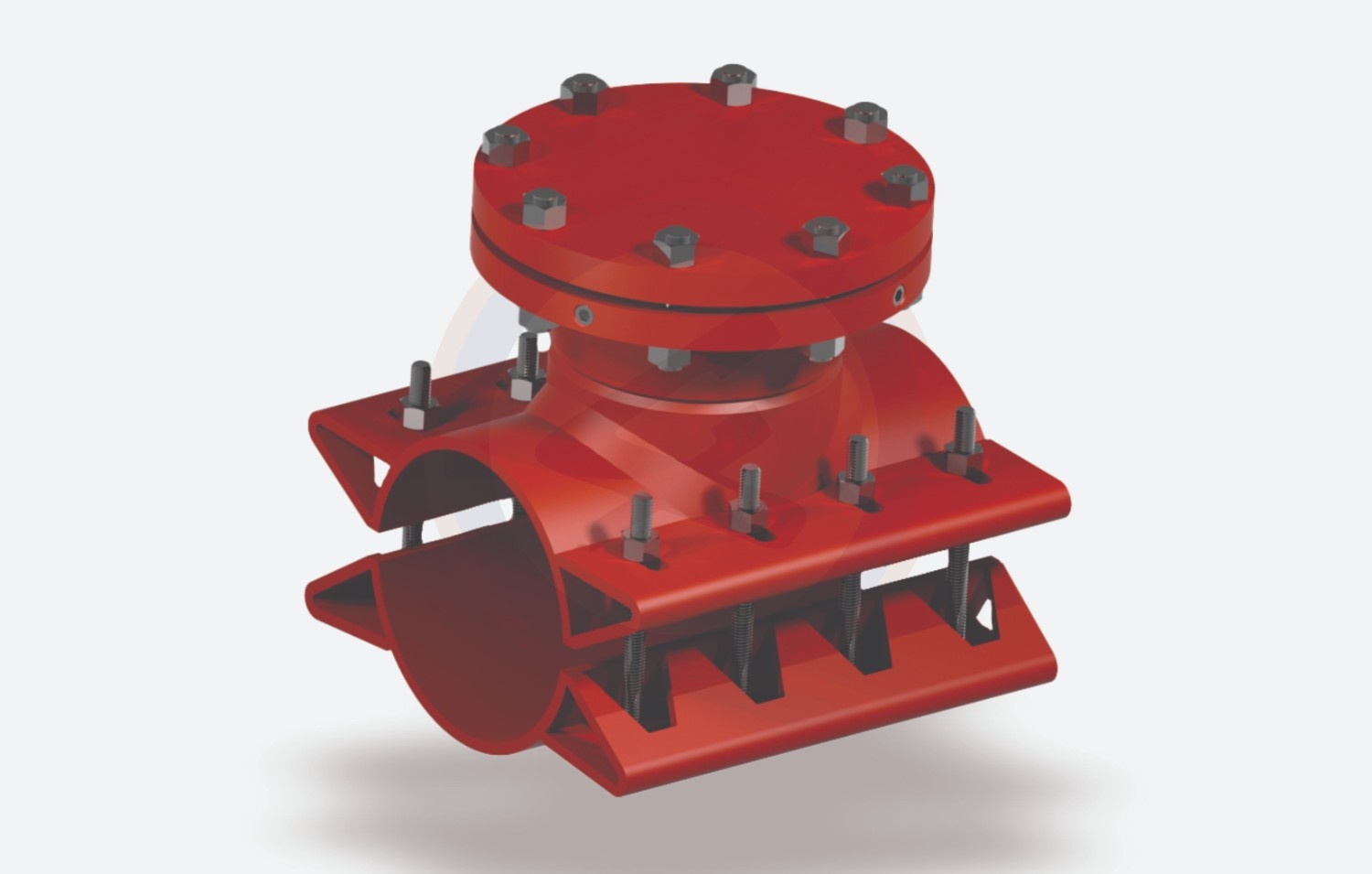

Hot Tap / Line Stop Mechanical Tees

Hot Tap Mechanical Tee

Line Stop Mechanical Tee

These Hot Tap / Line Stop Mechanical Tees are similar in design and construction to full encirclement split tees, but instead of welding, these split tees are fastened to the mainline using fasteners on both longitudinal sides. These are generally recommended for low-pressure operations.

| Sizes | Pressure Rating |

|---|---|

| 2 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) | ANSI 150# & PN SERIES |

Hot Tapping Nozzle

Flanged Nozzle with RF Pad

Flanged Nozzle with RF Pad are used in hot tapping operations where the tapping size is smaller than the mainline size. These fittings are of fabricated type.

Flanged Nozzle

Flanged Nozzle are typically used in situations where the design pressure of the pipeline is relatively low. These fittings are of fabricated type.

Weld-O-Let Flange

Weld-O-Let Flange are employed for hot tapping when the tapping size is significantly smaller than the mainline size. These fittings are of fabricated type.

| Fittings | Sizes | Pressure Rating |

|---|---|---|

| Flanged Nozzle with RF Pad | 2 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) | ANSI 150# & PN SERIES |

| Flanged Nozzle | 2 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) | ANSI 150# & PN SERIES |

| Weld-O-Let Flange | 2 Inch to 48 Inch (Above 48 Inch can be supplied against specific request/Order) | ANSI 150# & PN SERIES |

Thread-O-Ring Fitting

Thread-O-Ring Fitting are specialized components essential for line stopple operations. They facilitate pressure balancing between the mainline and the line stop operation system. These fittings also enable the draining and venting of the product from the isolated section.

| Sizes | Pressure Rating |

|---|---|

| 2 Inch & 3 Inch | ANSI 150#, 300#, 600# & PN Series |

Why Choose Hot Tap / Line Stop Fittings

- Enhances pipeline integrity for hot tapping or Line Stop Operation in the line stopper fitting.

- Versatility across different pipe materials, sizes, and pressure ratings.

- Compliance with international industry standards delivering reliable and safe performances.

Key Features of Hot Tap / Line Stop Fittings

- Safely modify or isolate pipelines without shutting down operations.

- Wide size range from ½” to 48” with high-pressure ratings.

- Compatible with mild steel, carbon steel, and stainless steel.

- Available in split tees, 3-way tees, nozzles, and mechanical tees.

- Advanced fittings ensure pressure balance, draining, and venting.

- Designed to ASME code standards for safety and reliability.

Why F4?

- Unmatched Manufacturing Capability: F4 is the only company in India producing specialized pipeline fittings and equipment in a wide range of sizes and design pressures across multiple product lines.

- Complete In-House Expertise: With state-of-the-art manufacturing, its own design team, and in-house testing, F4 ensures precision, quality, and reliability in every product.

- Standards-Driven & Custom-Focused: All fittings are built to ASME code for high and low-pressure lines, with customized solutions tailored to each client’s technical needs and site conditions.

Frequently Asked Questions

- 1: How do Hot Tap and Line Stop Fittings help during pipeline maintenance and modifications?

- 2. What size range and pressure ratings are available for F4’s pipeline fittings?

- 3: How do hot tapping and line stopping fittings improve the safety and reliability of the pipeline?

- 4: What makes F4 different from other manufacturers of pipeline fittings?

- 5: Can Hot Tap / Line Stop Fittings be used with different pipe materials and environments?

These Fittings allow operators to safely connect new pipelines and also isolate the section of pressurized pipelines without the need for shutting them down. This allows smooth work of essential repairs, system modifications ,or any additional repairs without any interruption in the flow, which saves time and operational cost.

F4 produces Hot Tap / Line Stop Fittings ranging from ½” to 48” in size, and pressure ratings such as ANSI 150#, 300#, and 600#. Along with Custom sizes up to 102 inches and we also provide higher pressure ratings on special request, which are suitable for diverse Oil & Gas, Water, and Industrial applications.

These fittings are engineered with precision to maintain system integrity by enabling safe pressure balancing, draining, and venting of isolated sections.They will also prevent pipeline failure risks and allow modifications or repairs without any interruption , especially under high-pressure conditions.

With over three years of experience, along with a dedicated design and engineering team, high-class manufacturing, and in-house testing facilities, F4 delivers highly reliable Fittings that are customized according to any project requirement and industry standards (ASME,ANSI).

Yes. These fittings are compatible with mild steel, carbon steel, stainless steel, and other pipe materials. They are engineered in such a way that they can perform reliably across a wide range of operating environments, pipe diameters, and pressure ratings, making them highly versatile for oil, gas, water, and industrial pipelines.