Heat Exchanger/Hydro Blast Cleaning Equipment’s

- Heat Exchanger Bundle Puller

- UHP/ HP Hydro blast Pumping Units Diesel Engine/Electric Driven

- Single/Multiple Lance cleaning Machines

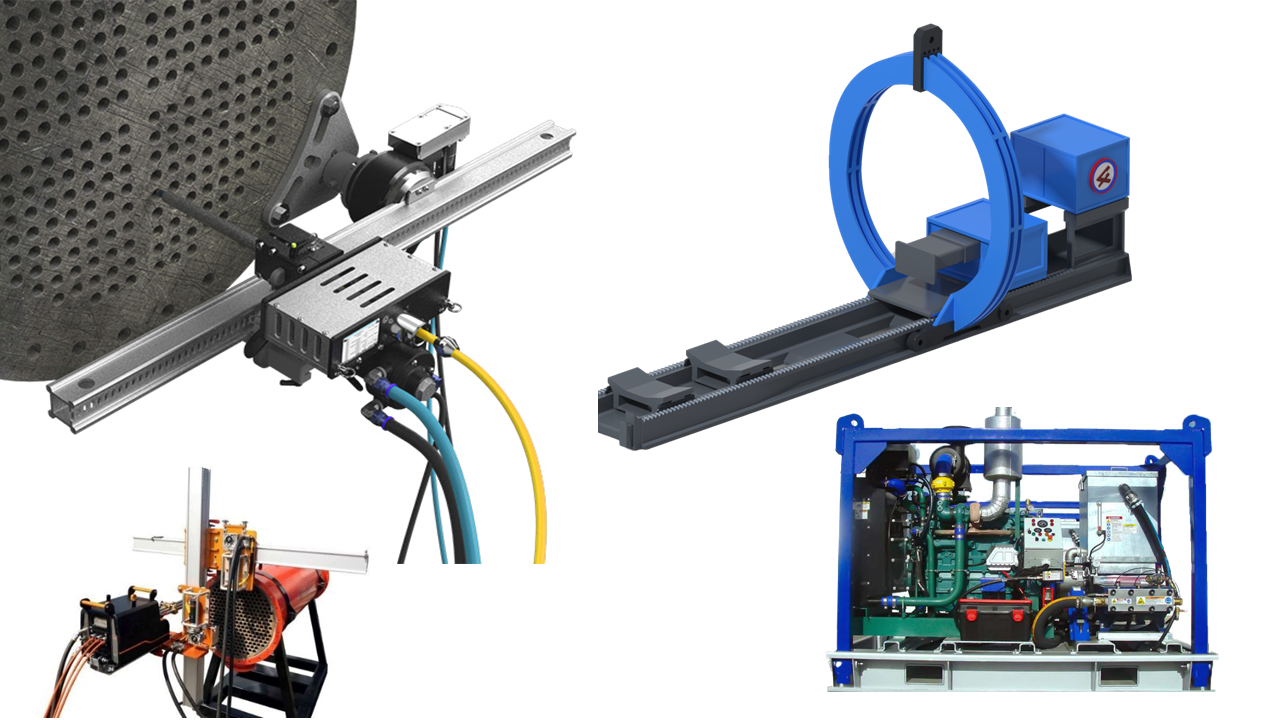

Heat Exchanger Bundle Puller

F4 offers a wide range of Aerial Tube Bundle Extractors in standard sizes from 20 tons to 60 tons and length right up-to 12 metre and diameter up-to 3m. Each Extractor is self-contained and can be lifted into position by just one crane, making on-site installation simple and easy. Our water jetting machines are impressively innovative whilst remaining invariably simple.

UHP/ HP Hydro blast Pumping Units Diesel Engine/Electric Driven

High Pressure water Jetting machines diesel driven and Electric motor driven up-to maximum 40,000 PSI (1400 bar) and flow rate of max. 120LPM. This Pressure range and flow rate meet the various cleaning requirements of most industrial applications like Ship Hull Cleaning, Paint & Rust Removal, Surface Cleaning, Surface Preparation, Concrete Demolition (Hydro Demolition), Kiln Cleaning in Cement Plant, Tank Cleaning with Special Nozzles, Tube cleaning, Hydro milling and many more industrial applications. Machine is supplied with standard accessories like Gun, Hose, Foot pedal, Rigid lances, Flexible lances and required nozzles.

Single/Multiple Lance cleaning Machines

To save time, human exposure and cleaning quality we have developed multi lance cleaning system for heat exchanger tube internals. With this system, time required for cleaning is decreased. It also eliminate requirement for chemical circulation before water jetting. High pressure and high flow can be achieved as there is no human involvement. Lances can be remotely controlled by operator from safe place.

Specialized Heat Exchanger Hydro Jetting Equipment

F4 hydrojetting technology for heat exchangers is designed to be flexible and efficient for a vast array of heat exchanger geometries, including:

- Shell and tube heat exchangers

- Plate heat exchangers

- Fin fan heat exchangers

- Condensers and evaporators

- Every system is crafted with precision hardware to provide dependable performance in tough industrial applications.

Industries Served by Our Heat Exchanger Hydro Blast Cleaning Equipments

F4 hydroblast heat exchanger cleaning equipment finds application in numerous industries, such as:

- Oil and gas refiners

- Petrochemical factories

- Power generation plants

- Chemical processing facilities

- Mining operations

- Food and drinks production

Maintenance and Support Services

Along with our high-quality heat exchanger cleaning equipment, F4 provides complete maintenance and refurbishment services for all your equipment requirements. Our technical experts offer skilled servicing and repair of heat exchanger cleaning machines of any brand, keeping your cleaning processes uninterrupted.

F4’s dedication to quality goes beyond equipment supply to encompass:

- Operator training programs

- Preventive maintenance schedules

- Emergency repair services

- Equipment upgrades and retrofits

Why Select F4 for Your Heat Exchanger Hydro Jetting Requirement?

As a specialist in manufacturing and supplying quality industrial maintenance equipment since 2014, F4 Holdings has carved a niche for itself. Our commitment to engineering quality and customer satisfaction has established our heat exchanger hydroblast cleaning equipment as the first choice among maintenance professionals across the globe.

FAQs

- 1. How do heat exchanger hydroblast cleaning equipments differ from conventional cleaning methods?

- 2. How frequently should I clean my equipment with heat exchanger cleaning tools?

- 3. Are F4 heat exchanger hydrojetting systems eco-friendly?

- 4. Can your heat exchanger cleaning machines be customized for specific applications?

- 5. What safety features are built into your heat exchanger hydroblast cleaning equipment?

Our heat exchanger hydroblast cleaning equipment utilizes high-pressure water (up to 20,000 PSI) to remove deposits completely from tube surfaces, unlike mechanical methods that might leave residue behind. This results in more thorough cleaning and better restoration of heat transfer efficiency.

The frequency is based on your particular application and operating conditions. Typically, we suggest checking heat exchangers every quarter and cleaning as required with our heat exchanger cleaning tools. Units in extreme environments might need to be cleaned more often.

Yes, our heat exchanger hydrojet systems are based mainly on water pressure and not on aggressive chemicals, so they are more eco-friendly. Nevertheless, proper wastewater management is needed since the cleaning process can produce contaminated water that needs to be handled properly.

Absolutely. F4 produces and engineers heat exchanger cleaning machines that may be specifically tailored to suit specific working needs. Our team of engineers collaborates closely with customers to create specific solutions for uncommon heat exchanger setups.

Safety is a primary design requirement in all of our heat exchanger hydro blast cleaning equipment. The features include remote operation control, emergency shutdown systems, pressure relief valves, and extensive safety interlocks. We also provide extensive operator training to facilitate safe operation of all equipment.