Advanced Industrial Catalyst Handling Vacuum Systems

F4 is Asia’s premier pipeline maintenance manufacturing company and a trusted industrial vacuum equipment supplier, providing industrial vacuum systems and catalyst handling services with advanced solutions for industries like petrochemical, refinery, and chemical processing. Our state-of-the-art industrial central vacuum system technology ensures safe and efficient loading and unloading operations while minimizing downtime and maximizing productivity.

Revolutionary Industrial Catalyst Handling Vacuum Systems Technology

The industrial central vacuum system from F4 embodies decades of engineering excellence and innovation. As a leading catalyst company and industrial vacuum manufacturers in Asia, we provide self-contained, closed-loop industrial wet dry central vacuum system solutions that ensure the safe extraction, transfer, and recovery of catalyst materials. Working with pyrophoric materials can expose catalysts to air and moisture, but our industrial technology enables handling under inert conditions to prevent self-ignition and maintain workplace safety. Systems can be tailored to transfer catalysts directly into totes, trucks, dumpsters, or collection devices.

- Super Sucker Vacuum Trucks Wet / Dry

- Industrial ( Catalyst Handling) Vacuum Units ( Dry/Wet)

- Filter Units

- Cyclone Hopers – Single Chamber with CDV or Slide Valve| Double Chamber

- After Coolers ( Exhaust Air Coolers)

Super Sucker Vacuum Trucks Wet / Dry

F4 manufactures powerful industrial vacuum equipment for wet and dry operations. Our vacuum truck loaders offer reliable cleanup and containment of hazardous and corrosive liquids. These trucks utilize high-powered airflow to pneumatically convey solids, semi-solids, sludge, and slurries, ensuring safe transport without environmental hazards.

Industrial ( Catalyst Handling) Vacuum Units ( Dry/Wet)

Dry

The unloading process is generated using roots blower pumps driven by diesel engines or flame-proof motors. Our dry units feature suction capacities ranging from 2500–5000 m³/hr @ –22” hg, enabling pneumatic conveyance of catalyst or ceramic balls from high reactors. Compact, transportable, and easy to maintain, this design exemplifies the efficiency of a central vacuum system.

Wet

Our wet units employ liquid ring pumps powered by diesel engines or explosion-proof motors. These systems can convey solids, semi-solids, or high-viscosity liquids under both inert and ambient conditions. Designed for portability and efficiency, these units highlight why F4 is a trusted industrial vacuum equipment manufacturer in Asia.

Pneumatic (Air) Driven

F4 offers portable vacuum catalyst unloading units that are pneumatically driven. With 540m³/hr vacuuming capacity at 7-bar input, these units are ideal for catalyst skimming, dust collection, and reformer tube cleaning. Compact and safe for hydrocarbon zones, they reflect the strength of our industrial vacuum cleaner manufacturer’s solutions

Filter Units

F4 manufactures specialized catalyst filter units for wet and dry operations. Equipped with timer-controlled pulse jet cleaning systems, these filters handle aggressive conditions like high temperatures and corrosive chemistry, reinforcing our expertise as a top industrial vacuum equipment supplier.

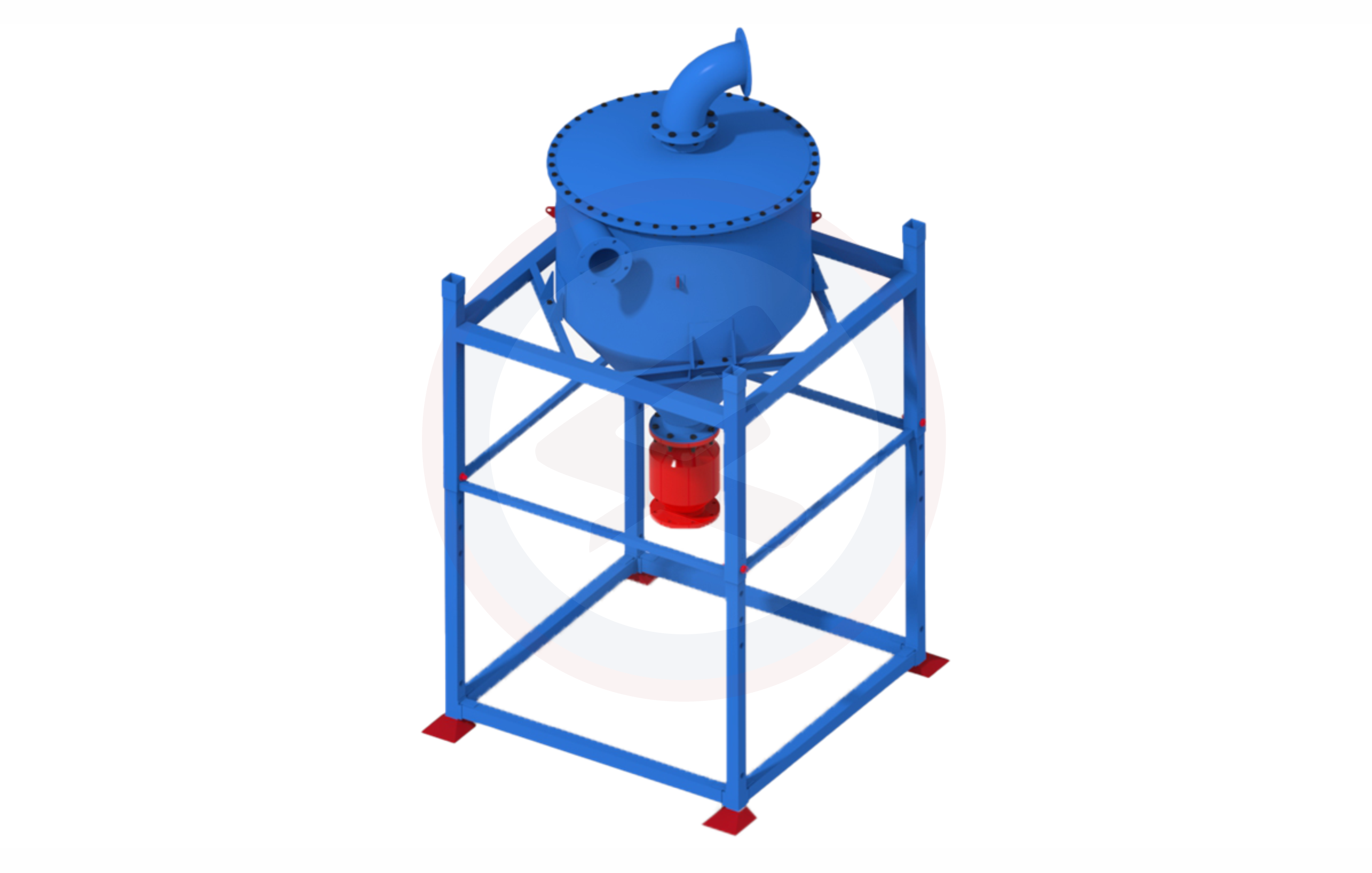

Cyclone Hopers – Single Chamber with CDV or Slide Valve| Double Chamber

As a global catalyst handling company, F4 produces cyclone hoppers to enhance vacuum pump performance. Offering continuous suction and intermittent discharge through pneumatically operated valves, these hoppers are engineered with precision by one of the leading vacuum system manufacturers in Asia.

Single Chamber

Double Chamber

After Coolers ( Exhaust Air Coolers)

Our after-coolers manage nitrogen temperature control by using plate/tube exchangers, cooling between 30–40°C before recirculation. These innovative designs are part of our advanced industrial solutions.

Why choose Advanced Industrial Catalyst Handling?

- Ensures safe unloading and inert handling of sensitive catalysts.

- Uses advanced industrial vacuum systems and central vacuum system technology.

- Trusted handling company and equipment manufacturer across industries.

Key Features of Advanced Industrial Catalyst Handling

- F4, a top catalyst handling company, provides advanced vacuum systems.

- Our industrial wet dry central vacuum system enables safe vacuum catalyst unloading.

- Leading equipment manufacturer delivering efficient industrial central vacuum system solutions.

- Vacuum system industrial technology ensures secure handling of sensitive catalysts.

- Trusted vacuum equipment supplier and industrial vacuum manufacturers across industries.

- Expert industrial vacuum cleaner manufacturers and vacuum system manufacturers for high-performance operations

Why Choose F4 Holdings for Industrial Catalyst Handling

- Industry-Leading Expertise in Industrial Vacuum Systems

As a premier catalyst handling company and one of Asia’s top vacuum equipment manufacturers, we offer unmatched expertise in designing and deploying advanced vacuum systems. - Comprehensive Range of Industrial Vacuum Equipment

F4 manufactures and supplies a wide array of industrial vacuum equipment, including central vacuum system units, portable vacuum catalyst unloading solutions, filter units, and wet/dry vacuum trucks. - Cutting-Edge Technology for Safe Catalyst Handling

Our vacuum systems and industrial solutions are engineered to safely handle pyrophoric and sensitive catalysts under inert conditions. preventing exposure to air or moisture.

Frequently Asked Questions

- 1. What Is an Industrial Catalyst Handling Vacuum System?

- 2. How Do These Vacuum Systems Improve Safety?

- 3. Can these vacuum systems Handle Different Catalyst Types?

- 4. How do I select the right vacuum system for my industrial catalyst handling needs?

It’s a closed-loop vacuum system industrial setup designed for safe extraction, transfer, and recovery of catalysts under inert conditions, preventing pyrophoric risks.

Our vacuum systems feature closed-loop operation, explosion relief valves, and inert handling capabilities. These designs, crafted by one of Asia’s premier vacuum system manufacturers, maximize operator safety during catalyst processing.

Yes. F4’s vacuum system is engineered for various catalyst types, including pyrophoric types requiring inert handling. That is the reason why F4 is recognized among the top cleaner manufacturers in the region.

First, share your project details, catalyst type, volume, site conditions, and other requirements with our team. As a trusted industrial vacuum equipment manufacturer, we provide tailored solutions that ensure optimal safety, efficiency, and performance.