Hot Tapping Machines

Hot Tapping Machine Overview

A Hot Tapping Machine is a specialized device that enables the connection or modification of existing pipelines without requiring a shutdown. It is an under-pressure tapping method used to maintain the system running and cut safely into pressurized lines. The machine provides a secure, effective, and airtight process for forming branch connections or installing line stops. F4 manufactures and designs These Machines that align with international standards and can meet the strict project needs. We offer equipment with a wide selection of diameters and pressure ratings, which makes it flexible in the industries. Operators can keep the services running, minimize the downtime, and make the systems more flexible .

- 6 Series & 8 Series

- 12 Series

- 17 Series

- 24 Series

- 36 Series & 42 Series

- 48 Series

- 96 Series

- Pressure Balancing Tapping Machines

- Tribar Hot Tapping Machines

- Worm Gear Driven Hot Tapping Machine

6 Series & 8 Series

| Model | F4 6-18 | F4 6-24 | F4 6-28 | F4 6-30 | F4 8-40 |

|---|---|---|---|---|---|

| Tapping Range | ½ Inch – 4 Inch | ½ Inch – 4 Inch | ½ Inch – 4 Inch | ½ Inch – 4 Inch | 2 Inch – 8 Inch |

| Boring Bar Travel Length | 18 Inch | 24 Inch | 28 Inch | 30 Inch | 40 Inch |

| Cutter Housing Mounting Size | 2 Inch BSP Male Nipple | 2 Inch BSP Male Nipple | 2 Inch BSP Male Nipple | 2 Inch BSP Male Nipple | 2 Inch BSP Male Nipple |

| Power Source for Drive | Manual/ Pneumatic/ Electrical | Manual/ Pneumatic/ Electrical | Manual/ Pneumatic/ Electrical | Manual/ Pneumatic/ Electrical | Manual/ Pneumatic/ Electrical |

F4 12-42

The F4 Hydraulic Tapping System is designed for industrial applications, engineered to be precise and reliable, and capable of handling tapping sizes ranging from 3 to 12 inches, with a 42-inch boring bar travel. This hot tap machine for pipeline operates hydraulically and represents an ANSI 4-inch 600# RTJ cutter housing. The F4 hydraulic tapping unit is made in such a way that it can meet the tests and demands that are important for delivering consistent power across the industries.

| Specification | F4 Hydraulic |

|---|---|

| Tapping Range | 3 Inch – 12 Inch |

| Boring Bar Travel Length | 42 Inch |

| Cutter Housing Mounting Size | ANSI 4 Inch 600# RTJ |

| Power Source for Drive | Hydraulic |

| Recommended Hydraulic Power Unit | F4-HPU-2-21-200 |

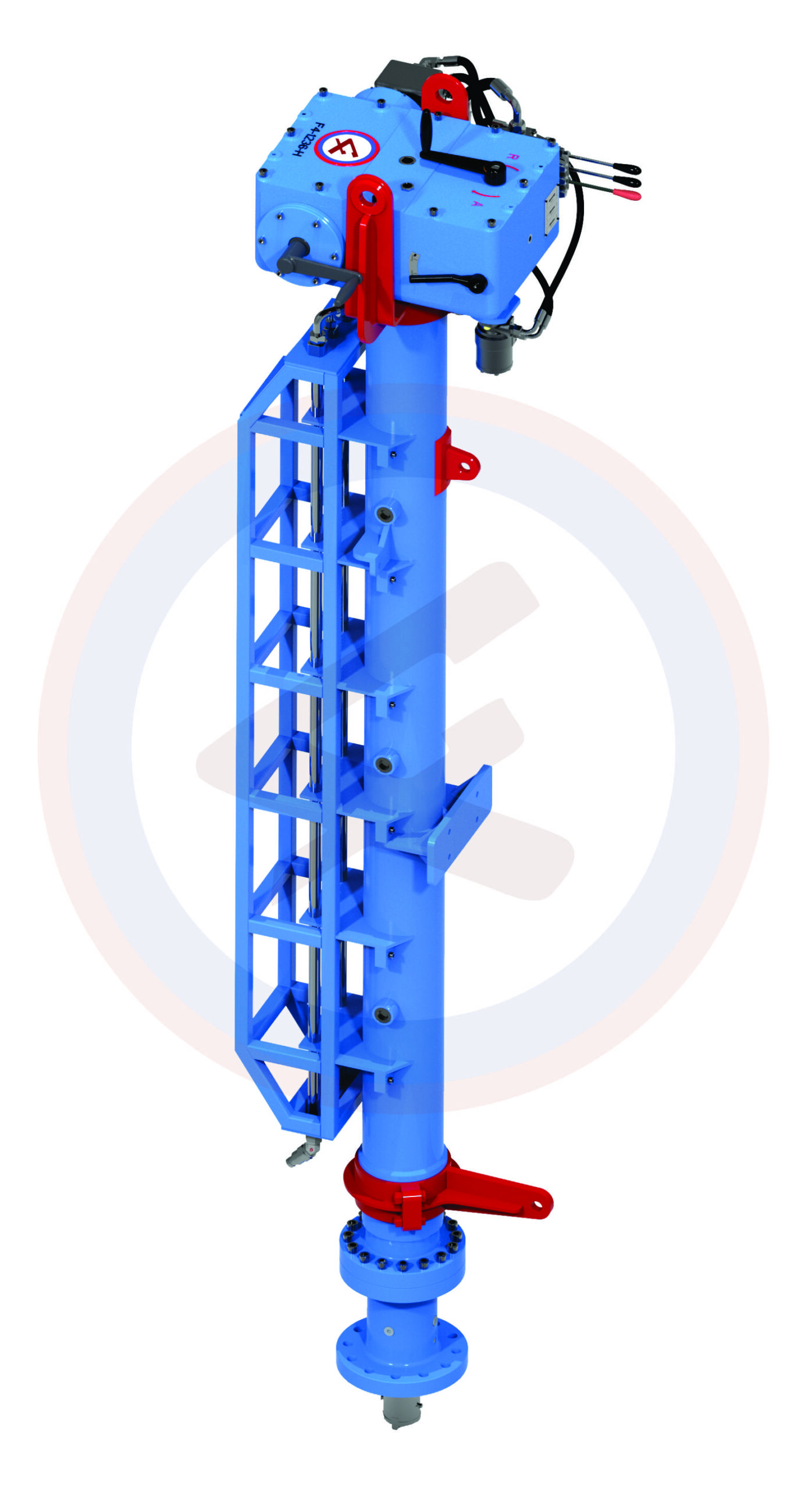

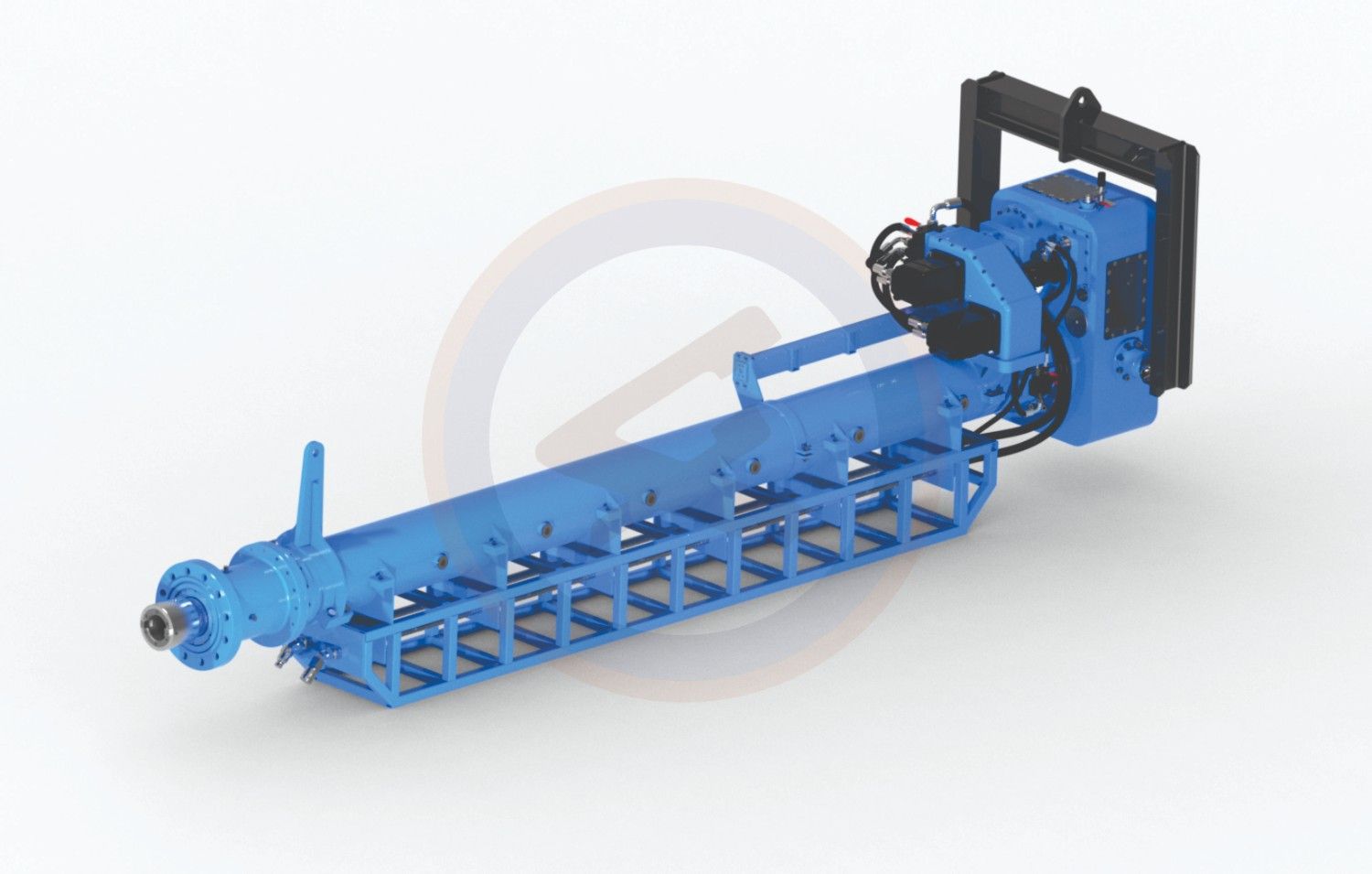

F4 17-66

The F4 17-66 Hydraulic tapping system is designed to perform larger tapping operations on a 3 to 18-inch pipeline and a 66-inch boring bar travel capacity. It has an ANSI 4-inch 600# RTJ cutter housing and a hydraulic drive that provides powerful performance under high-demand industrial conditions.

| Specification | F4 Hydraulic (Extended) |

|---|---|

| Tapping Range | 3 Inch – 18 Inch |

| Boring Bar Travel Length | 66 Inch |

| Cutter Housing Mounting Size | ASNI 4 Inch 600# RTJ |

| Power Source for Drive | Hydraulic |

| Recommended Hydraulic Power Unit | F4-HPU-2-27-300 |

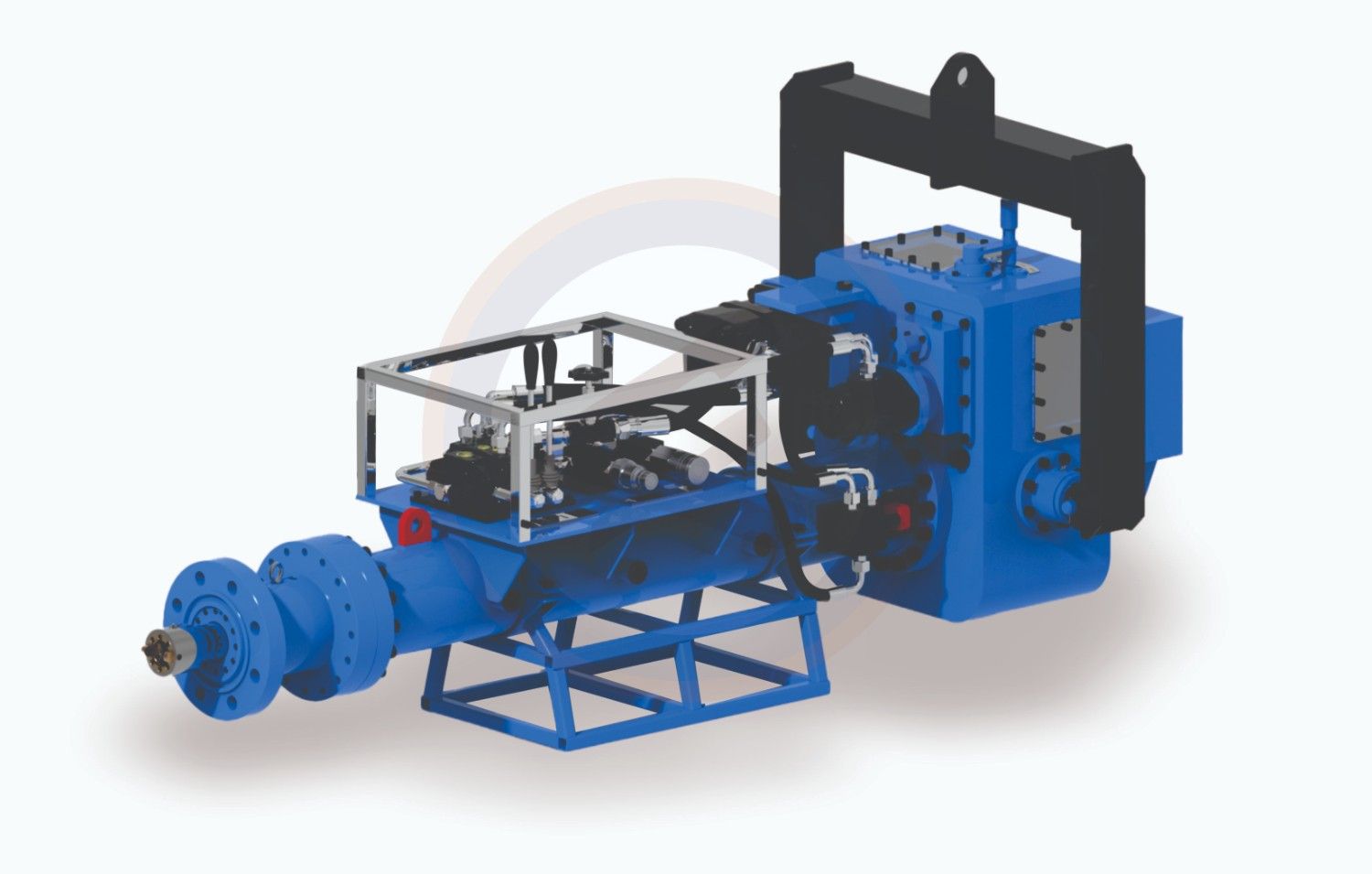

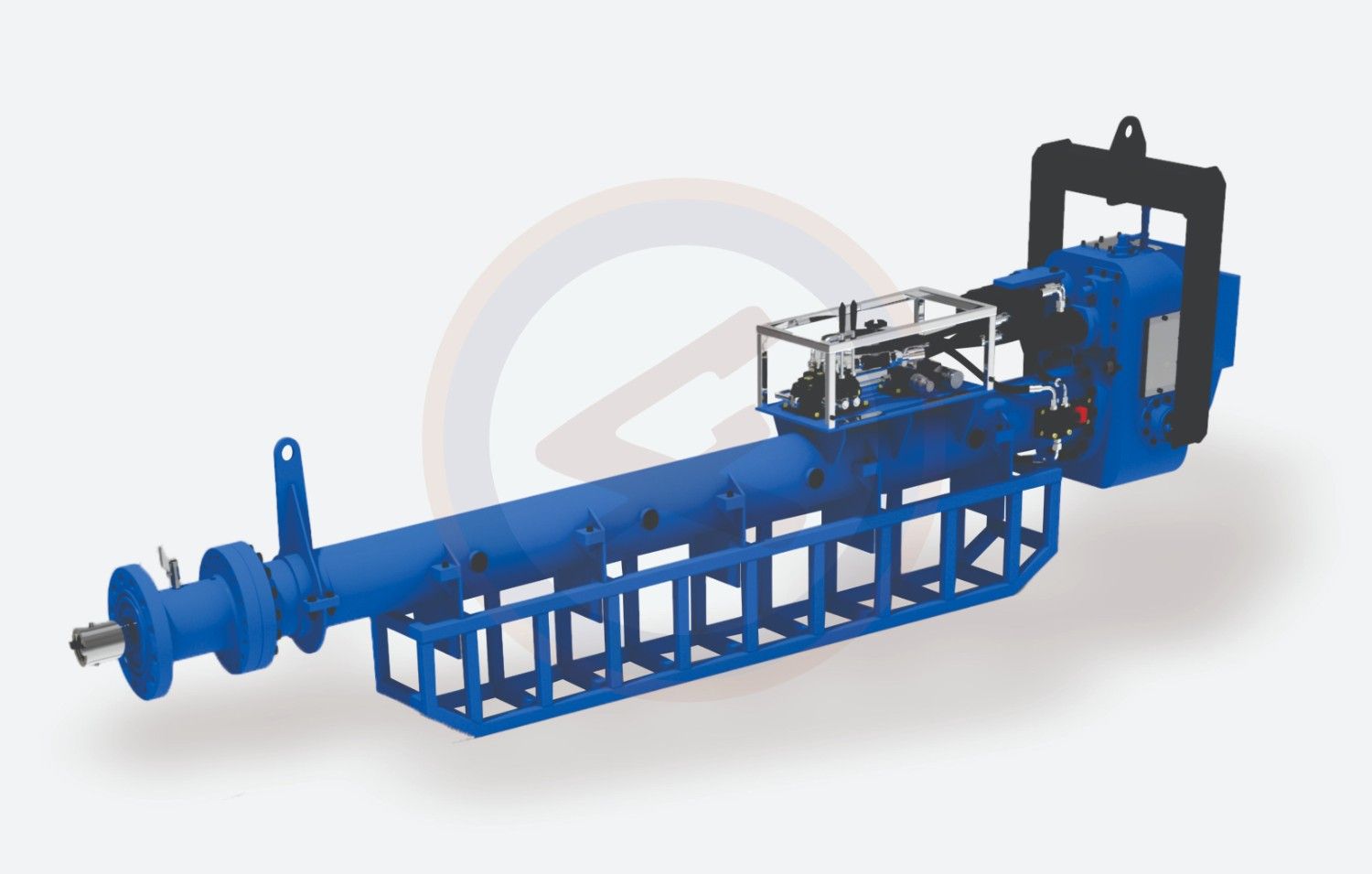

F4 24-72

The F4 24-72 Hydraulic tapping system is designed to operate with mid-to-large diameter pipelines, and is capable of tapping 6-inch to 24-inch pipelines with a 72-inch boring bar travel capacity. It is built with an ANSI 4-inch 600# RTJ cutter housing and is hydraulically powered, ensuring reliability even in the hardest working conditions.

| Specification | F4 Hydraulic (Extended) |

|---|---|

| Tapping Range | 6 Inch – 24 Inch |

| Boring Bar Travel Length | 72 Inch |

| Cutter Housing Mounting Size | ASNI 4 Inch 600# RTJ |

| Power Source for Drive | Hydraulic |

| Recommended Hydraulic Power Unit | F4-HPU-2-27-300 |

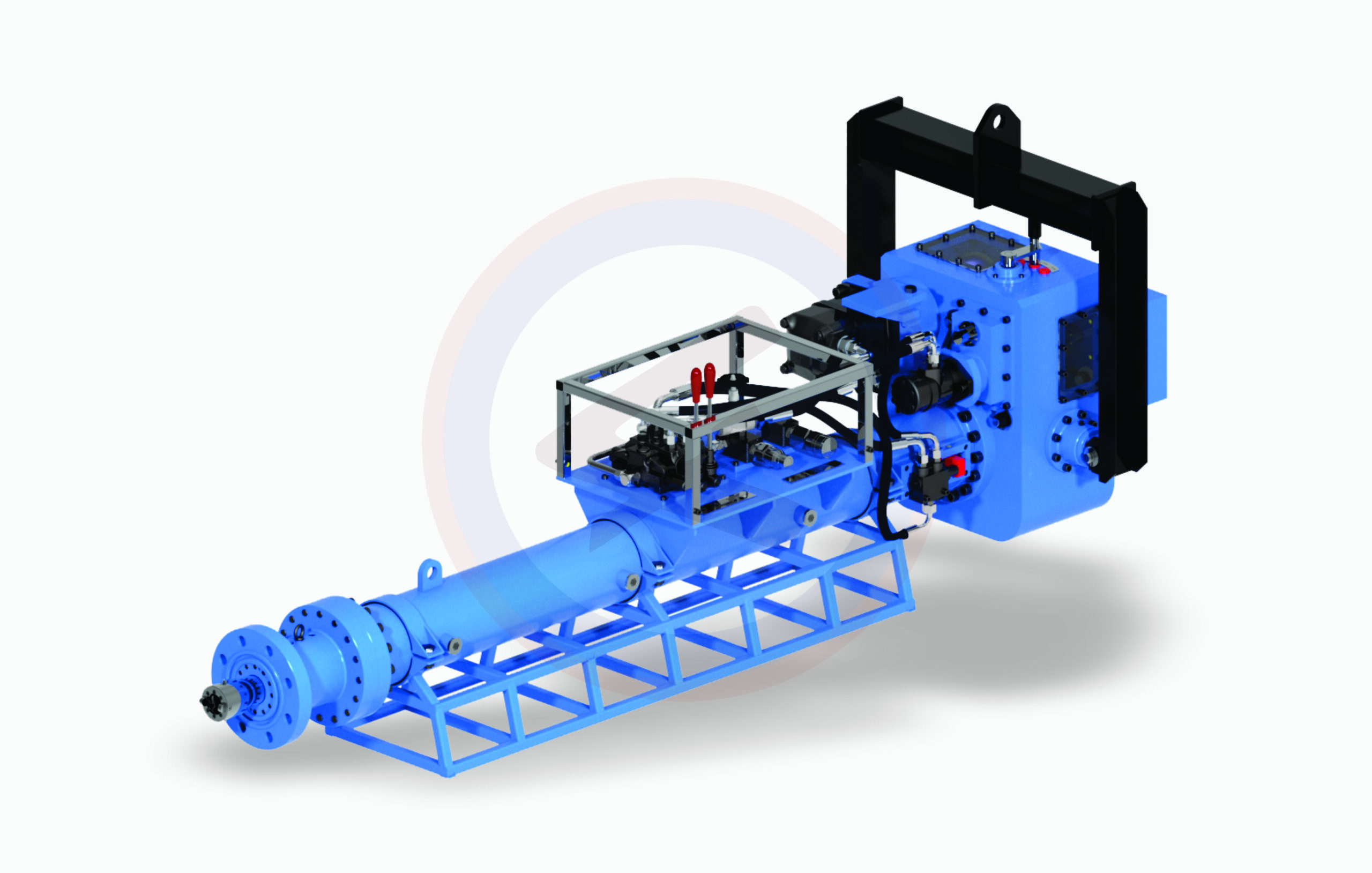

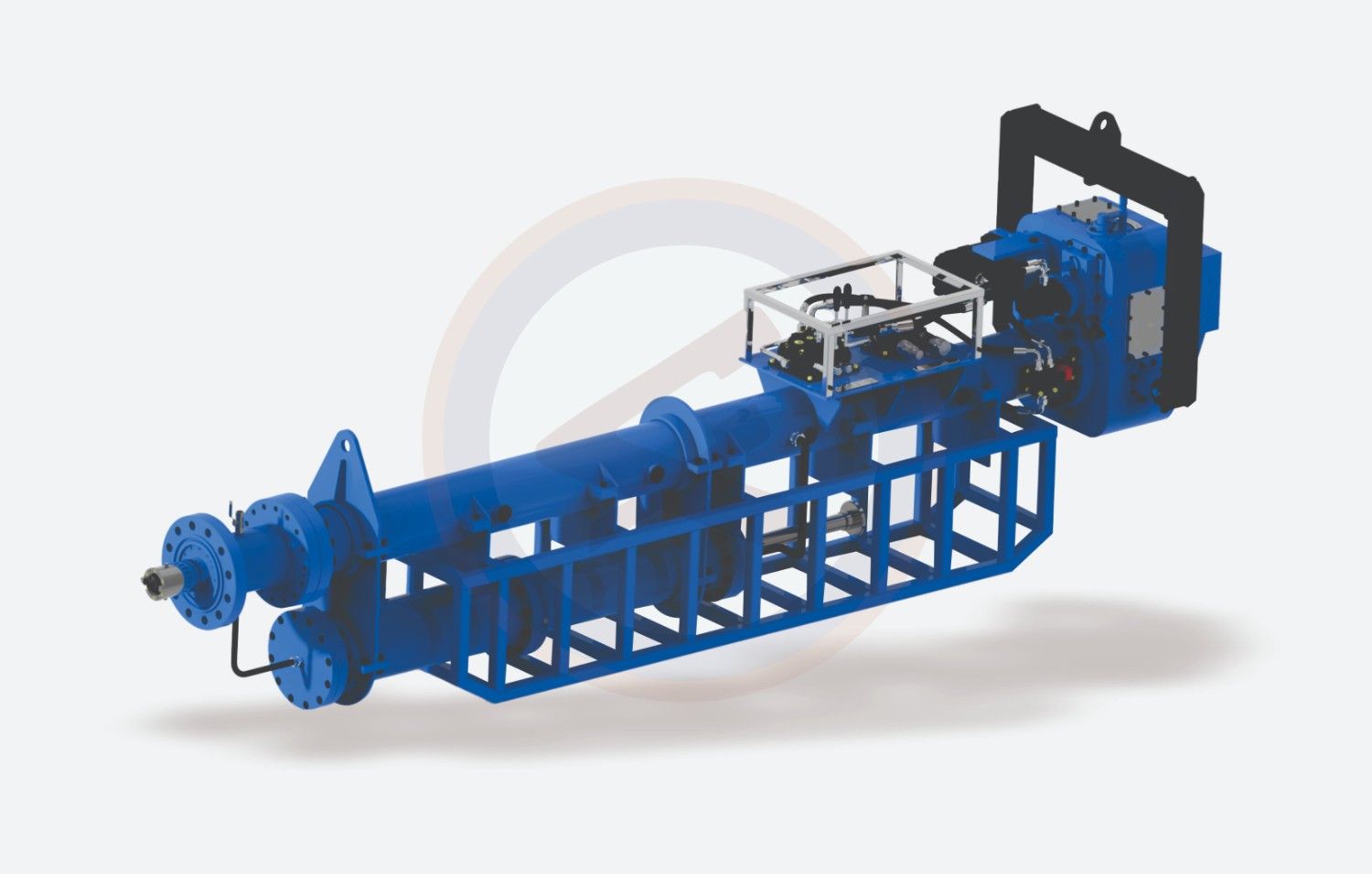

36 Series & 42 Series

The F4 36 Series & 42 Series hydraulic tapping systems for large-diameter pipeline projects with a tapping range of 12-42 inches. They are built for power and precision with up to 120 inches of boring bar travel capacity and an ANSI 6-inch 600# RTJ cutter housing suitable for high-pressure and heavy-duty operations.

| Model | F4 36-80 | F4 36-108 | F4 42-120 |

|---|---|---|---|

| Tapping Range | 12 Inch – 36 Inch | 12 Inch – 36 Inch | 12 Inch – 42 Inch |

| Boring Bar Travel Length | 80 Inch | 108 Inch | 120 Inch |

| Cutter Housing Mounting Size | ANSI 6 Inch 600# RTJ | ANSI 6 Inch 600# RTJ | ANSI 6 Inch 600# RTJ |

| Power Source for Drive | Hydraulic | Hydraulic | Hydraulic |

| Recommended Hydraulic Power Unit | F4-HPU-3-27-400 | F4-HPU-3-27-400 | F4-HPU-3-27-400 |

48 Series

The F4 48 Series hydraulic tapping systems are designed to operate on extra-large diameter pipelines, along with bringing in a tapping capacity of 20 to 48 inches. They deliver power and precision with boring bar travel capacity up to 150 inches and an ANSI 8-inch 600# RTJ cutter housing.

| Model | F4 48-100 | F4 48-130 | F4 48-150 |

|---|---|---|---|

| Tapping Range | 20 Inch – 48 Inch | 20 Inch – 48 Inch | 20 Inch – 48 Inch |

| Boring Bar Travel Length | 100 Inch | 130 Inch | 150 Inch |

| Cutter Housing Mounting Size | ANSI 8 Inch 600# RTJ | ANSI 8 Inch 600# RTJ | ANSI 8 Inch 600# RTJ |

| Power Source for Drive | Hydraulic | Hydraulic | Hydraulic |

| Recommended Hydraulic Power Unit | F4-HPU-3-47-450 | F4-HPU-3-47-450 | F4-HPU-3-47-450 |

96 Series

| Model | F4 96-120 | F4 96-150 | F4 96-180 |

|---|---|---|---|

| Tapping Range | 24 Inch – 96 Inch | 24 Inch – 96 Inch | 24 Inch – 96 Inch |

| Boring Bar Travel Length | 120 Inch | 150 Inch | 180 Inch |

| Cutter Housing Mounting Size | ANSI 8 Inch 600# RTJ | ANSI 8 Inch 600# RTJ | ANSI 8 Inch 600# RTJ |

| Power Source for Drive | Hydraulic | Hydraulic | Hydraulic |

| Recommended Hydraulic Power Unit | F4-HPU-4-70-450 | F4-HPU-4-70-450 | F4-HPU-4-70-450 |

Pressure Balancing Tapping Machines

The tapping systems, manufactured by F4, have a pressure-balancing design with compensation cylinders. This design balances the pipeline and seawater pressure, which decreases stress on internal parts and increases the life of the equipment. These high-pressure and subsea tapping machines can operate up to 2175 psi (150 bar).

| Tapping Range | Power Source for Drive |

|---|---|

| 3 Inch – 36 Inch | Hydraulic |

| Model No. | Tapping Range | Boring Bar Travel Length | Cutter Housing Mounting Size | Recommended HPU |

|---|---|---|---|---|

| F4-17-66 PB | 3 Inch – 18 Inch | 66 Inch | ANSI 4 Inch 600 / 900# RTJ | F4-HPU-2-27-300 |

| F4-24-72 PB | 6 Inch – 24 Inch | 72 Inch | ANSI 4 Inch 600 / 900# RTJ | F4-HPU-2-27-300 |

| F4-36-80 PB | 12 Inch – 36 Inch | 80 Inch | ANSI 6 Inch 600 / 900# RTJ | F4-HPU-3-27-400 |

| F4-36-108 PB | 12 Inch – 36 Inch | 108 Inch | ANSI 6 Inch 600 / 900# RTJ | F4-HPU-3-27-400 |

| F4-42-120 PB | 12 Inch – 42 Inch | 120 Inch | ANSI 6 Inch 600 / 900# RTJ | F4-HPU-3-27-400 |

Tribar Hot Tapping Machines

Hot tapping machine manufacturers like F4 produce lightweight portable Tribar machines, which are suitable for low-pressure utility services, including chilled water pipelines in air conditioning systems or air/nitrogen pipelines in pharmaceutical and food processing. These units allow bypasses or branching of pipelines and are especially applicable in locations that have limited space, like malls, hotels, and data centers. The lightweight compact nature of the tribar machines enables the installation without lifting devices and easy transportation to any floor within the high-rise buildings using the lift.

F4’s compact tribar systems are engineered for pipeline repair or replacement, ensuring uninterrupted processes.

| Model No. | Tapping Range | Boring Bar Travel Length | Cutter Housing Mounting Size | Recommended HPU |

|---|---|---|---|---|

| F4-312 TBM | 3 Inch – 12 Inch | 30 Inch | ANSI 8 Inch 150# | F4-PHPU-1-17-40 / F4-EHPU-3P-5-40 |

| F4-616 TBM | 6 Inch – 16 Inch | 40 Inch | ANSI 8 Inch 150# | F4-PHPU-1-17-40 / F4-EHPU-3P-5-40 |

| F4-312 TBMG | 3 Inch – 12 Inch | 30 Inch | ANSI 8 Inch 150# | F4-PHPU-1-17-40 / F4-EHPU-3P-5-40 |

| F4-616 TBMG | 6 Inch – 16 Inch | 40 Inch | ANSI 8 Inch 150# | F4-PHPU-1-17-40 / F4-EHPU-3P-5-40 |

Worm Gear Driven Hot Tapping Machine

F4 manufactures worm gear-driven equipment and hydraulic hot tapping equipment. These hot tap machines are for sale, providing reliable performance

Air Driven Hot Tapping Machines are available in following ranges

| Model No. | Tapping Range | Boring Bar Travel Length | Cutter Housing Mounting Size | Air Consumption |

|---|---|---|---|---|

| F4-208 A | 2 Inch – 8 Inch | 30 Inch | ANSI 2 ½ Inch 600# RTJ | 6-7 Bar @ 90 CFM |

| F4-312 A | 3 Inch – 12 Inch | 42 Inch | ANSI 4 Inch 600# RTJ | 6-7 Bar @ 90 CFM |

| F4-316 A | 3 Inch – 16 Inch | 66 Inch | ANSI 4 Inch 600# RTJ | 6-7 Bar @ 90 CFM |

Hydraulic Driven Hot hot-tapping machines with the same design are available below

| Model No. | Tapping Range | Boring Bar Travel Length | Cutter Housing Mounting Size | Recommended HPU |

|---|---|---|---|---|

| F4-208 H | 2 Inch – 8 Inch | 30 Inch | ANSI 2 ½ Inch 600# RTJ | F4-HPU-2-21-200 |

| F4-312 H | 3 Inch – 12 Inch | 42 Inch | ANSI 4 Inch 600# RTJ | F4-HPU-2-21-200 |

| F4-316 H | 3 Inch – 16 Inch | 66 Inch | ANSI 4 Inch 600# RTJ | F4-HPU-2-21-200 |

| F4-624 H | 6 Inch – 24 Inch | 72 Inch | ANSI 4 Inch 600# RTJ | F4-HPU-2-21-200 |

| F4-1236 H | 12 Inch – 36 Inch | 80 Inch | ANSI 6 Inch 600# RTJ | F4-HPU-3-27-400 |

| F4-1236 HXL | 12 Inch – 36 Inch | 108 Inch | ANSI 6 Inch 600# RTJ | F4-HPU-3-27-400 |

| F4-1242 H | 12 Inch – 42 Inch | 120 Inch | ANSI 6 Inch 600# RTJ | F4-HPU-3-27-400 |

| F4-2048 H | 20 Inch – 48 Inch | 100 Inch | ANSI 8 Inch 600# RTJ | F4-HPU-4-70-450 |

| F4-2048 HXL | 20 Inch – 48 Inch | 130 Inch | ANSI 8 Inch 600# RTJ | F4-HPU-4-70-450 |

| F4-2048 HXXL | 20 Inch – 48 Inch | 150 Inch | ANSI 8 Inch 600# RTJ | F4-HPU-4-70-450 |

| F4-2460 H | 24 Inch – 60 Inch | 150 Inch | ANSI 8 Inch 600# RTJ | F4-HPU-4-70-450 |

Key Features and Application of Our Hot Tapping

- Repair or replacement of the pipeline sections using the hot tap rental and sale service.

- Pipelines, tie-in, re-routing, or bypass operation.

- Decommissioning or abandonment of the pipeline.

- Replacement or repair of the valves.

- Testing and leak verification of the repaired pipelines.

- Removal of the pipeline dead legs.

Why Choose F4

- Expert Engineering

Innovative designs constructed to perform under phenomenal pressures, temperatures, and diverse types of pipeline materials. - End-to-End Support

Consistent project implementation, planning, and commissioning high standards of safety. - Tailored Solutions

Optimized for efficiency, safety, and long-term reliability, custom-built machinery.

Frequently Asked Questions

- 1. How do I select the right hot tapping machine for any pipeline project?

- 2. What safety standards and certifications do F4 machines have?

- 3.Will F4 provide hot tapping machines for rent, or are they only for sale?

- 4. What kind of training or manpower is required to operate a hydraulic hot tapping machine?

- 5. How quickly can spare parts or service be arranged?

- 6. Are these machines suitable for offshore or subsea projects?

- 7. What are the typical applications of a hot tapping machine?

Selection basically depends on the operating pressure, the material, the pipe diameter, and the site conditions. F4 provides consultation on how to choose the right machine specifications based on your pipeline requirements.

Here in F4, hot tapping machines meet international oil and gas industry standards, which include ANSI, ASME, and API guidelines, ensuring reliability and safety.

Yes, F4 provides hot tap machine rental services along with sales. Still, it is only for selected tapping machines, making it easier to manage short-term or project-oriented requirements without a full capital investment.

F4 provides training to operators along with technical support. Depending on the machine’s size, basically smaller hot tapping machines for pipeline can be handled by in-house teams, while larger systems may require trained F4 technicians.

F4 maintains a ready stock of high-demand spare parts and provides field service teams to ensure minimal downtime during critical operations for any hot tapping equipment.

Yes. These pressure-balancing hot tapping machines for pipelines are specifically built for subsea use, permitting safe operation even under seawater pressure conditions.

These machines are used for a variety of industrial purposes, such as pipeline repair or replacement, valve installation or repair, tie-ins and re-routing, bypass operations, pipeline decommissioning, dead leg removal, and leak verification tests.