Catalyst ( Bulk Material) Handling Equipment’s | Accessories | Consumables

Catalyst handling refers to the careful process of removing used or spent catalysts from reactors and replacing them with fresh ones. This is a critical step typically carried out in refineries and other processing plants to keep operations running smoothly and efficiently.

- Delta Pressure Testing

- Sieving Machines with Various size Screens

- Shifting Hopper / Loading Hopper

- Drum Roller Benches

- Catalyst Bins with PVC Bag Liners

Delta Pressure Testing

This instrument can measure pressure loss or pressure resistance in the tube in reformer tubes from tube diameters of 50-150 mm and length upto 14m.

Sieving Machines with Various size Screens

This Sieving Machine mechanically segregates different sizes of catalyst and ceramic balls simultaneous with the help of 4 screens into 5 fractions. We can control vibration and rotation speed of catalyst inside the machine with counter weight adjustment of Motor. Stainless Steel Screens of required sizes and dimensions (Square/Rectangle opening) are fabricated as per the client requirement.

Shifting Hopper / Loading Hopper

F4 Manufactures hopper which has efficient flow rate and easy handling during operations. The Shifting Hopper is used to transport catalyst from ground level to the loading Hopper which is placed on top of the reactor. These hopper have a top cover lid to protect the handled Catalyst from moisture and to keep the hopper dry inside. We have specially designed valves for easy operations as valve of shifting hopper has to be operated in Suspended position.

The Loading Hopper is used to load Catalyst in a controlled and uniform manner inside the reactor. It has adjustable legs to suit different manways sizes and site conditions. It consists of a sliding valve to control flow rate of the Catalyst. As entrant has to frequently enter and exit during loading operation hoppers are designed in acentric conical shape to avoid obstacles for man entry.

Shifting Hopper

Loading Hopper

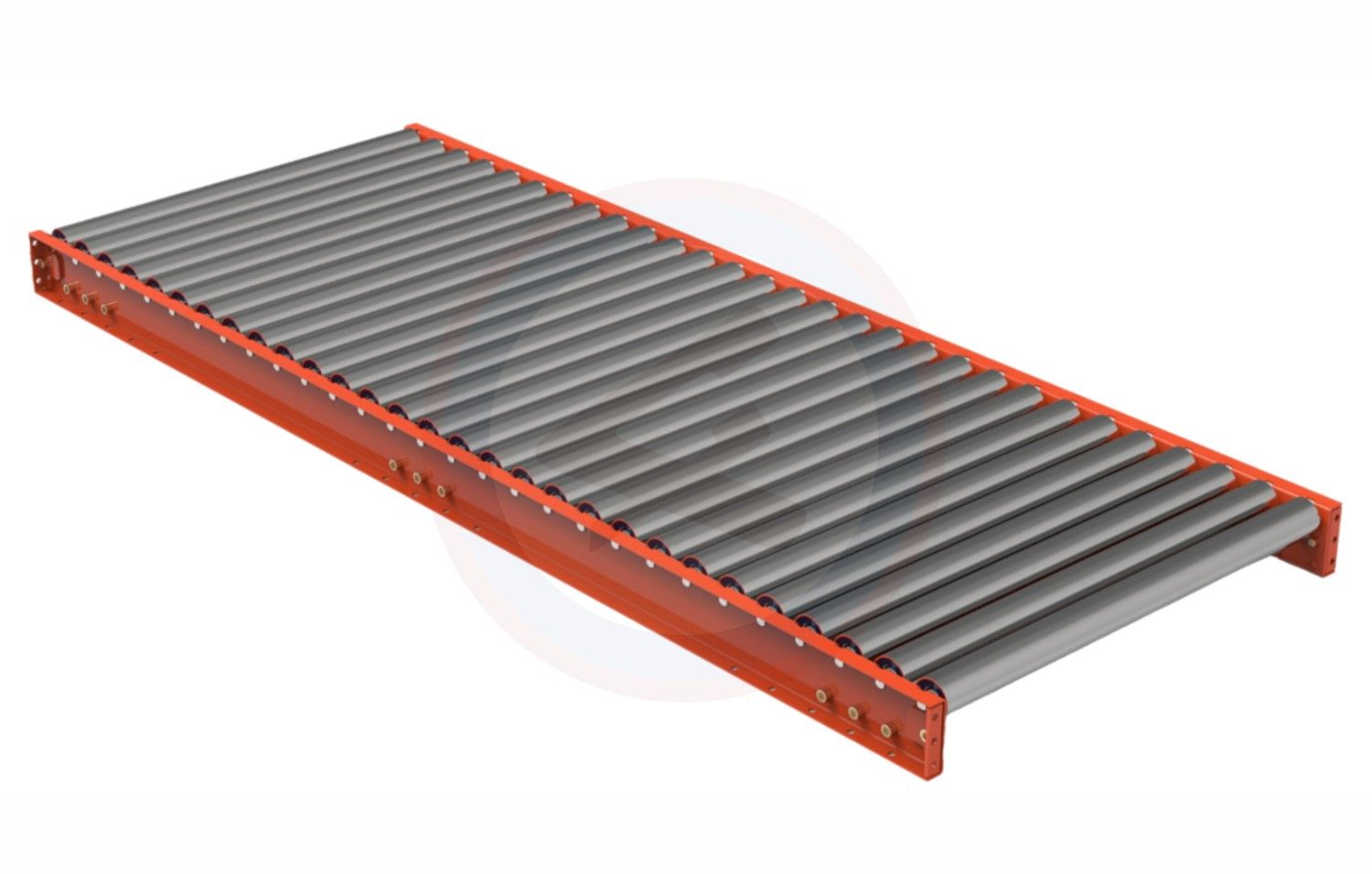

Drum Roller Benches

F4 Manufactures efficient Gravity Rollers which can effortlessly Transport a Single Piece of Material with a Large Weight like all kinds of Boxes, Bags, Pallets and Drums. Roller benches are used for faster dispersion of spent catalyst drums from the discharge point. Our roller benches are light weight and easy to fit up.

Catalyst Bins with PVC Bag Liners

Our Catalyst Bins provide a cost effective alternative to drums or bags for the transportation and storage of spent, pre-activated and fresh hydro processing catalysts. Our bins are designed for easy handling (Four way fork lift entry) and transportation. They have Flip top lid for easy loading and rectangular slide gate for easy discharge. These Catalyst Bins can be stacked two high to reduce storage requirements.

Key Features

- It comprises of

- Screening of the catalyst of various sizes

- Shifting / Unloading hopper for shifting and transferring the catalyst into the reactor from the top

- Loading of catalyst

- Catalyst bins for the transportation and storage of spent, pre-activated and fresh hydroprocessing catalysts.

Why Choose F4 for Catalyst Bulk Material Handling Equipment Accessories Consumables?

- The following are a few of the reasons why you should choose F4 for Catalyst bulk Material Handling Equipment Accessories Consumables:

Expertise You Can Trust:

With years of hands-on experience, our team truly understands the ins and outs of catalyst handling. We don’t just offer services but also provide custom solutions designed to fit your exact needs.

Built to Perform, Built to Last:

Our equipment is crafted for reliability. Known for its strong performance, long-lasting durability, and low-maintenance design, it ensures your operations stay safe, smooth, and efficient.

Support That Stays With You:

We’re here for you even after the job is done. From regular maintenance to quick access to spare parts, our after-sales support ensures you’re never left on your own.

FAQs

- What are catalyst bulk material handling equipment ?

- How do I choose the right supplier?

These are specialized tools designed to facilitate the safe and efficient handling of bulk catalysts in industrial processes. These equipment include shifting / unloading hoppers , drum rollers , catalyst handling bins etc.

When selecting a supplier for catalyst bulk material handling equipment accessories consumables, look for companies with proven expertise in your industry. Consider manufacturers like F4 that offer customizable solutions tailored to specific needs while adhering to international safety standards.