What Does a Mechanical Folding Line Stop Head Mean?What Benefits Does It Have for Pipeline Maintenance?

In a relatively simple world of pipeline maintenance and modifications, a single term can be brought up frequently and still remain unknown to many: the Mechanical Folding Line Stop Head. Although it might seem technical (and it is), the idea is nothing less than a brilliant engineering when the downtime is not an option.

We are not in the business of manufacturing pipeline equipment only, but we are in the business of engineering solutions at F4 Engineering (India) Private Limited. This blog reveals the identity of a mechanical line stop, its functionality, as well as the reason why it is a ground-breaking element in the pipeline intervention technology.

So, What Is a Line Stop?

A line stop is a procedure of temporarily isolating the flow of a live pipeline to allow pipeline maintenance, repair, or modification to be performed downstream, without having to shut down the whole system. This will be revolutionary to sectors such as oil and gas, utilities, and chemical plants, where any disruption could cost millions.

And this is where the folding head comes in.

What Is a Mechanical Folding Line Stop Head?

Imagine that the line stop head is the heroic plug that blocks the fluid that runs in the pipeline–but with a twist.

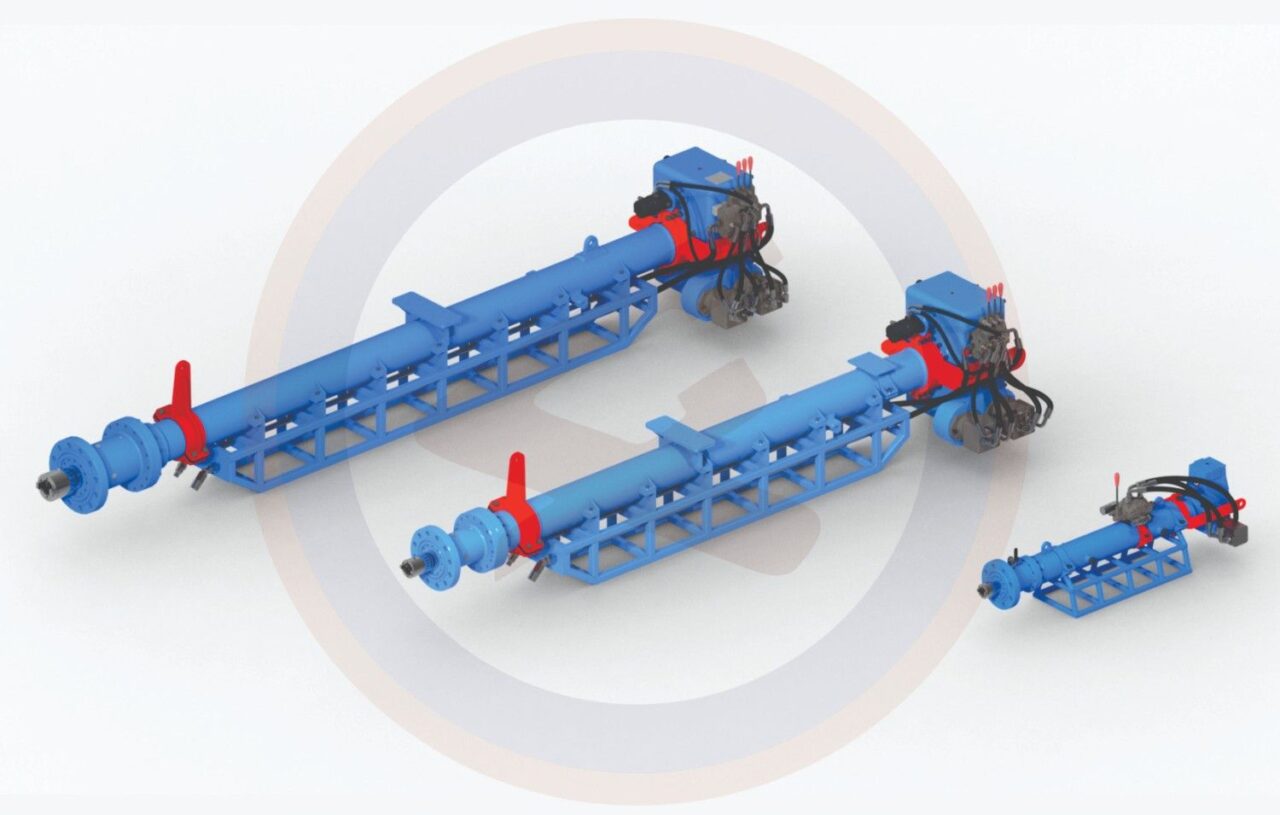

The folding head, unlike the conventional line stop heads, is designed in such a way that it collapses (folds) during insertion and unfolds (expands) after insertion into the pipeline. This is some smart engineering, since it can easily enter through a smaller opening, and can securely seal once deployed, even at high pressure.

Our folding heads at F4 are accurately manufactured to suit a large variety of diameters and pressures. They are applied together with hot tapping systems, and they can be utilized with welded or mechanical fittings.

So, Why Use a Folding Head?

The following are the excellent features that make the folding line stop head a favorite in the industry for pipeline maintenance:

- No Shutdowns. Zero Downtime.

It is a way to make changes to an active pipeline without having to shut down operations, as with sensitive processes such as water supply or chemical flow. This makes it an ideal pipeline shutdown tool.

- High-Pressure Tolerance

The folding heads designed by F4 to work in high-pressure environments have an adjustable pressure rating according to the requirements of a client. They are also made to comply with ASME requirements of safety and reliability.

- Compact Insertion. Efficient Deployment.

Since the head is folded during entry, a small access point is all that is needed. This equates to little disturbance of the pipeline and reduced installation times.

- Flexibility in Materials & Sizes

Our folding heads adjust to a pipeline of any material, steel, ductile iron, or a special alloy. They come in a large variety of sizes and pressure classes- ANSI 150# up to 600# and larger.

- Safe Reversible

The system is completely retractable, and the pipeline can be put back into normal operation when the job is finished. Safety is in every fold.

Why choose F4 Engineering?

We are not the first Indian company that manufactures hot tap and line stop equipment, but we are the only company that has in-house manufacturing, customization, and global standard testing facilities under a single roof. This is vital for comprehensive pipeline maintenance solutions.

Our Mechanical Folding Line Stop Heads are built to work under tough conditions, whether it be in the refinery pipeline in the Middle East or utility lines in high-rise buildings. With the support of innovation, performance, and an experience of more than 10 years, F4 is the pipeline intervention frontline name in India.

Final Thought

Stop the head of the mechanical folding line. In a world where time equals money and shutdowns cost money, the mechanical line stop is the quiet workhorse that makes it all run, literally. For effective pipeline maintenance, these solutions are paramount.

When you are involved in pipeline modification, repair, or bypass jobs and need minimum disturbance and maximum productivity, then it is high time to contact the professionals.

Talk to F4 Engineering. We don’t just stop pipelines—we stop problems before they begin.