BA Life Support System

F4 makes its own advanced safety equipment designed for breathing apparatus technology used in inert or toxic environments. Our BA life support systems leverage advanced technology to ensure breathable air for technicians who work in confined spaces or harsh environment

BA Life Support System Technology

At F4, we’ve made big improvements in respiratory safety technology. Our top-quality BA life support systems use smart design to work their best when it matters most. As trusted suppliers, we know how important it is to have reliable equipment in inert conditions ..

Our BA life support units under goes numerous test to make sure they perform as per safety standards , even in the toughest conditions. Whether it’s very hot or freezing cold, the systems keep running smoothly.

- LSS Control Unit

- Breathing Air lines

- Breathing Air Masks

- Full Body harness

- Communication Unit

- Inspection Camera Unit

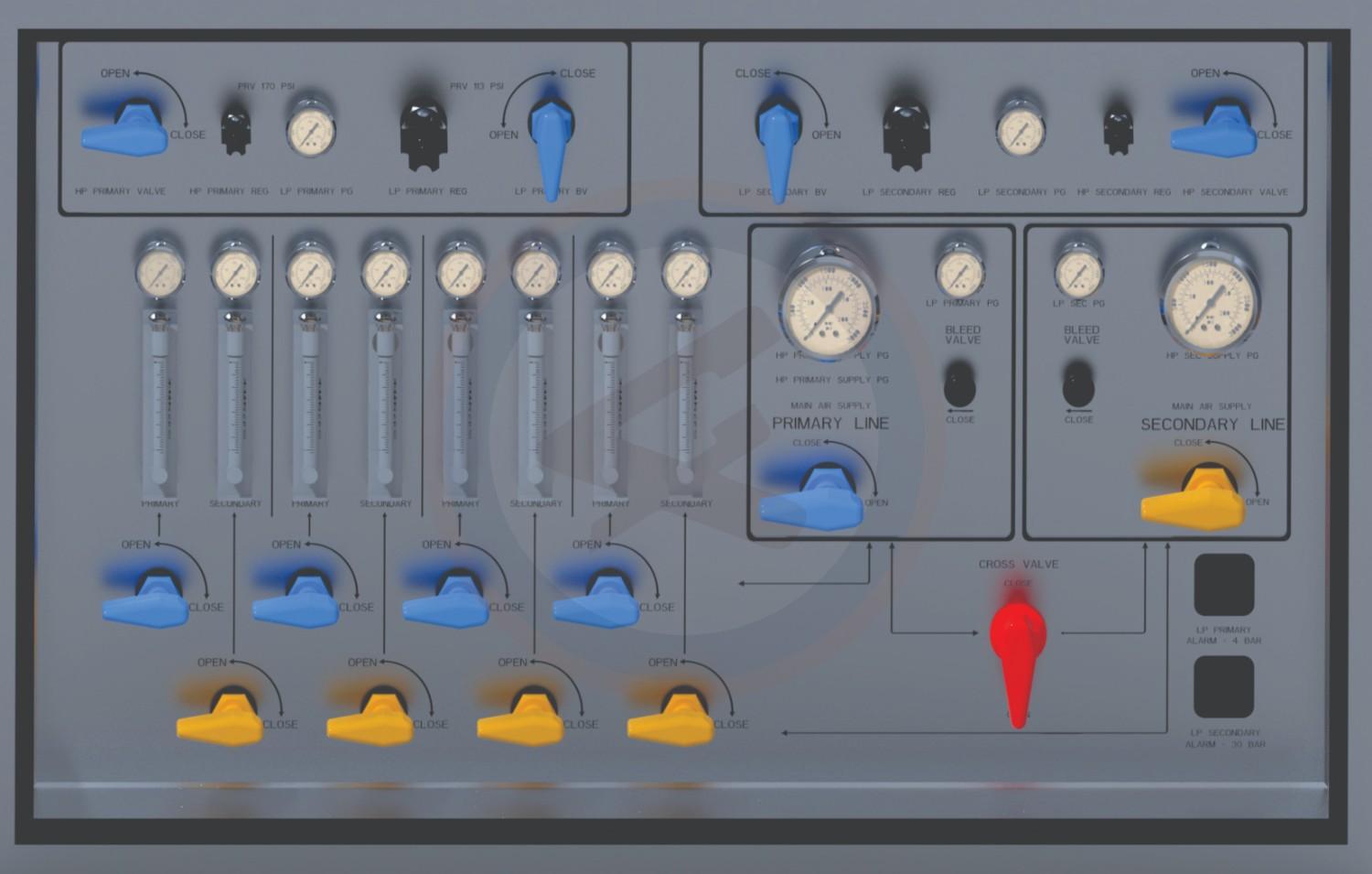

LSS Control Unit

Inert Atmosphere

The Life Support System enables safe working in nitrogen atmospheres. We supply complete life support system along with umbilical line, Communication system, Manifolds, Mask and Helmets.

Non-Inert Atmosphere

These systems are used in Non-Inert Atmosphere. It has pneumatic alarm system which alarm when primary air supply from cylinder drops below 30bar (High pressure side) and alarms at 4bar (low pressure side). Change over from primary to secondary is manual. It has built-in oxygen analyser. A Maximum of 4 users can use it at a given time.

Breathing Air lines

Our material used in our hoses safe and certified for breathing application. Our hoses comes with couplings that are quick and easy to connect. The hoses are made predominantly from polyurethane is a particularly clean and does not contain any potentially harmful additives. This ensures breathing gas quality is maintained under all Conditions from -40°C to +60°C. In addition polyurethane does not deteriorate significantly with age and remains flexible and abrasion resistant.

Single Airline From Panel A to B

High Pressure Hose

Single Breathing Line

Umbilical Lines

Breathing Air Masks

Anti-Panic Helmet

This Helmet comes with double breathing valve. It has integrated voice communication system and comes with Anti-Panic Locking system in case the entrant is under distress. An inflatable bladder inside the helmet allows for different head sizes to be accommodated. Because of its anti-panic respirator helmet with its independently working triple breathing air supply, integrated voice communication and camera monitoring as well as a height safety device, it’s a complete safety concept.

Breathing Air Masks

The Mask is connected to LSS through Umbilical lines and 3-Way Manifold. These mask are used in environments that are deprived of oxygen or has a hazardous atmosphere. The masks have demand valve for continuous supply of breathable air. The communication mic is used for communication purpose and it is installed inside the mask.

Full Body harness

Full Body Harness helps in easy rescue ensuring full safety with provision for fitting escape bottle and 3-Way Manifold blocks together for the Inert Entry Operations. Escape bottle will be used in case of failure of life supporting system. This manifold block is used to connect the Primary, Secondary Breathing hoses and the Escape bottle to mask through twin line hoses.

Communication Unit

Communication System with a maximum up-to 8 channels for ultra-clear communications and noise cancelling systems. It has In built black box and battery backup. This is a versatile piece of equipment, which could be used during the confined entry jobs.

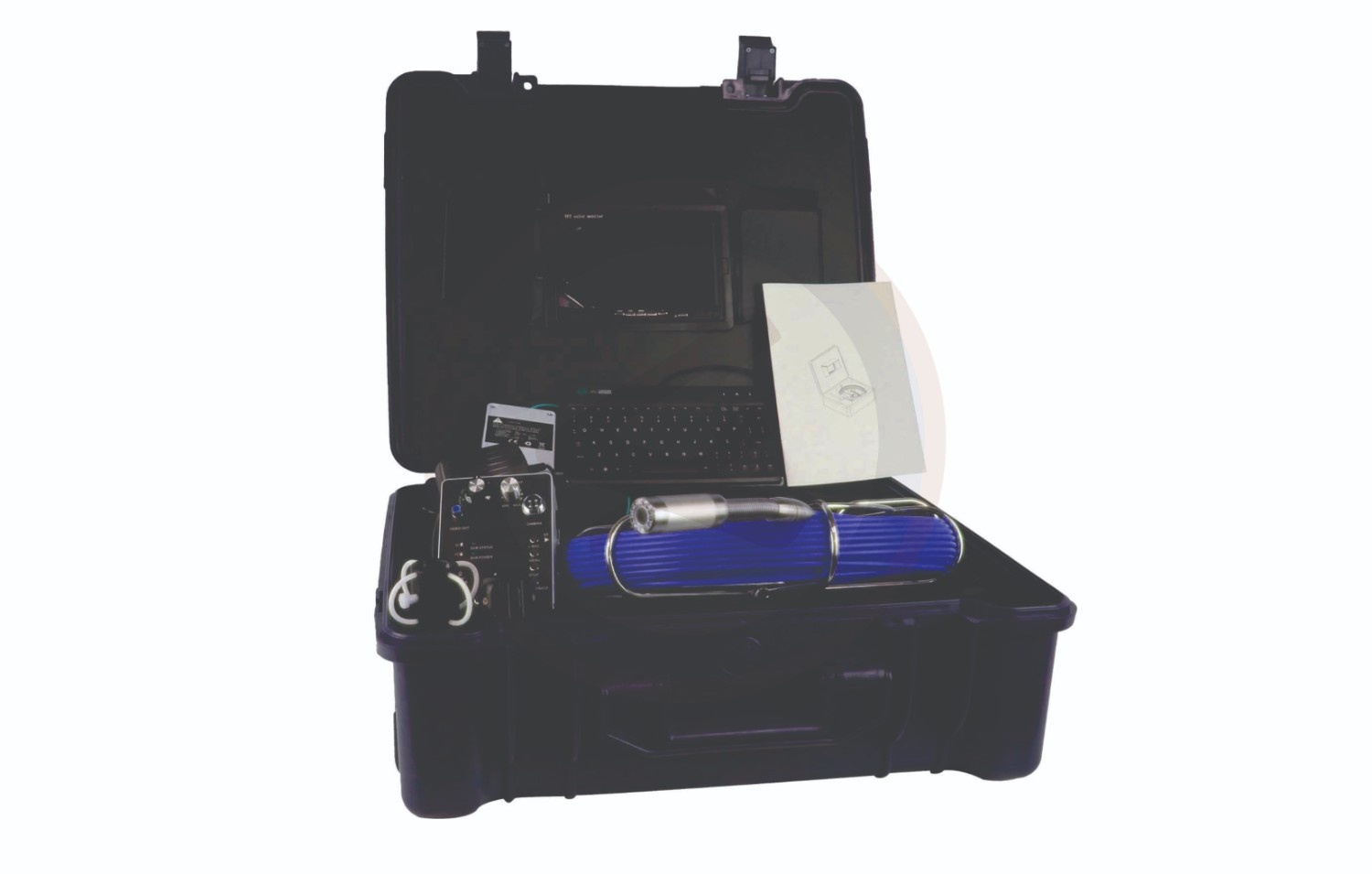

Inspection Camera Unit

These camera systems are used in monitoring the internal condition of the reformer tubes for cleaning, cracks, damage, coke deposition and scaling. Monitoring cameras are also used to monitor entrant inside confined spaces and also for inspections. The results are recorded for further verification & documentation Purpose.

Inspection Camera Unit

Explosion proof camera

Innovation and Compliance Leadership

F4 operates research laboratories that promote continuous development of their BA life support technology by their engineering departments. The continuous investment in product development keeps our company among the leaders in respiratory protection innovation. Our safety certification organization and regulatory body relationships enable us to forecast compliance demands while developing solutions that surpass current regulatory standards.

Service and Support Excellence

When you choose F4 for BA life support systems, you get full support from us. Our global service team helps with quick repairs, regular checkups, and expert advice. Certified technicians make sure everything works well and lasts longer.

We also offer training to teach users how to use the system and fix problems. Plus, our online platform is always available. It gives you access to guides, service schedules, and safety info anytime you need it.

BA Life Support System Technology

At F4, we’ve made big improvements in respiratory safety technology. Our top-quality BA life support systems use smart design to work their best when it matters most. As trusted suppliers, we know how important it is to have reliable equipment in inert conditions ..

Our BA life support units under goes numerous test to make sure they perform as per safety standards , even in the toughest conditions. Whether it’s very hot or freezing cold, the systems keep running smoothly.

Advanced Features of Our BA Life Support Solutions

Our BA life support gear is made to be easy to carry and use in tough places.These Life Support Systems are provided with Umbilical Lines & Air Hoses for confined spaces where Oxygen is present in scarce amounts. A Low Pressure Alarm System is also installed in the Life Support System..

Why Choose F4 as Their BA Life Support System Suppliers

F4 has attained global acclaim as a premier manufacturer of BA life support systems. Due to our unwavering dedication to innovation and quality, we have become the partner of choice for organizations that value the safety of their workers and the efficiency of their operations.

What differentiates us from other BA life support system suppliers is our approach to respiratory protection as a whole. We don’t just supply equipment — we also provide full support, including training, maintenance services, and help with meeting safety rules.

Our factories use advanced technology and follow strict quality standards that meet international rules.

As top manufacturers of BA life support systems, we check quality at every step — from testing each part to assembling and certifying the final product.

Because of our careful process, our respiratory protection equipment not only meets but often goes beyond safety requirements.

Applications Across Multiple Industries

- Emergency response and firefighting operations

- Hazardous material handling and chemical processing

- Confined space entry procedures

- Mining and underground operations

- Offshore oil and gas facilities

- Nuclear power plant maintenance

- Pharmaceutical manufacturing and research

Whether responding to urban emergencies or supporting complex industrial operations, professionals trust our BA life support system solutions to deliver reliable protection in oxygen-deficient or contaminated atmospheres. Our company understands worker challenges across various industries because we bring decades of experience manufacturing BA life support systems.

Frequently Asked Questions

- What makes F4 different from other BA life support system manufacturers?

- How often should BA life support systems be serviced?

- What training do you provide for BA life support system users?

- How does F4 ensure quality and reliability in their BA life support systems?

F4 distinguishes itself by providing LSS as per standards set by International Certifying Bodies, extended operational duration, and comprehensive support services that include training, maintenance, and compliance assistance. Our integrated approach to respiratory protection focuses on long-term partnership rather than simply supplying equipment.

The BA life support module should be inspected and tested before every vessel or reactor entry to ensure no damaged to the equipment as it would lead fatal accidents . F4 has guideline maintenance plans that are customized to fit your needs.

Our comprehensive training programs include standard operation, emergency procedures, troubleshooting, and maintenance essentials. The training facility also operates refresher courses alongside advanced technical maintenance training for clients’ maintenance teams.

Every part is carefully inspected and tested before utilizing it on the equipment.